ETALBOND®, ALUCOBOND®, DIBOND® oraz ALUCORE® ALBOND are leading brands of composite materials used in the construction and advertising industry. Find out what distinguishes the different composite materials and how to choose the right tools for processing them.

Advanced composite materials

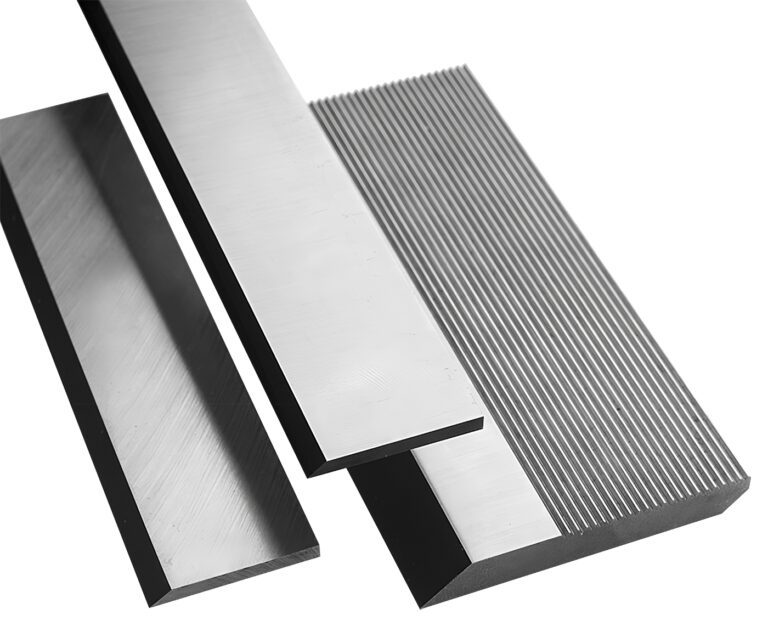

Thanks to a well-thought-out design based on the use of different materials, materials such as DIBOND, ETALBOND®, ALUCOBOND® and ALUCORE® ALBOND are characterised by their resistance to external influences, high functionality and adherence to the highest construction and visual standards. A wide range of colours, perfect flatness and easy shaping and processing - all this makes them very popular among consumers. However, to achieve the desired effect, the right tools are also needed for processing - but how to choose them?

DIBOND® in the advertising sector

Composite panels are also being successfully used in the advertising industry. In this case, DIBOND® deserves special attention. This is a composite panel made of thin, varnished aluminium top plates and an inner layer of polyethylene. Its construction makes the panel noticeably light despite its high rigidity. DIBOND® is machinable, making it easy to adapt it to many visual variations.

Which composite materials can be found on the market?

Nowadays, we can find a lot of products on the market that respond to customers' needs and expectations with innovative solutions. Composite panels are an excellent form of finishing in the construction and advertising sectors. They are increasingly used in roof constructions, facades, balconies, ceilings, partitions, advertising boards or signs.

ETALBOND® to A high-tech aluminium composite panel. In the range we can find:

- etalbond® PE with low-density polyethylene,

- etalbond® FR with a flame-retardant core,

- etalbond® A2 with a non-combustible core, suitable for the most demanding applications, meeting all fire protection requirements for external cladding.

ALUCOBOND® is a composite panel that consists of two aluminium outer sheets filled with a mineral core.

- ALUCOBOND® PLUS - Fire-resistant aluminium composite panel with mineral core,

- ALUCOBOND® A2 - Non-combustible aluminium composite panel with mineral core,

ALBOND – is a composite panel composed of two layers of varnished aluminium, filled with a polyethylene core. We can distinguish the following types:

- Albond® PE - with a combustible low-density polyethylene core,

- Albond® FR - with a polyethylene core with a higher flammability class,

- Albond® A2 - with ceramic core, non-combustible.

DIBOND® – aluminium and composite panel, which consists of two aluminium top layers and a polyethylene or mineral core.

How to process composite materials?

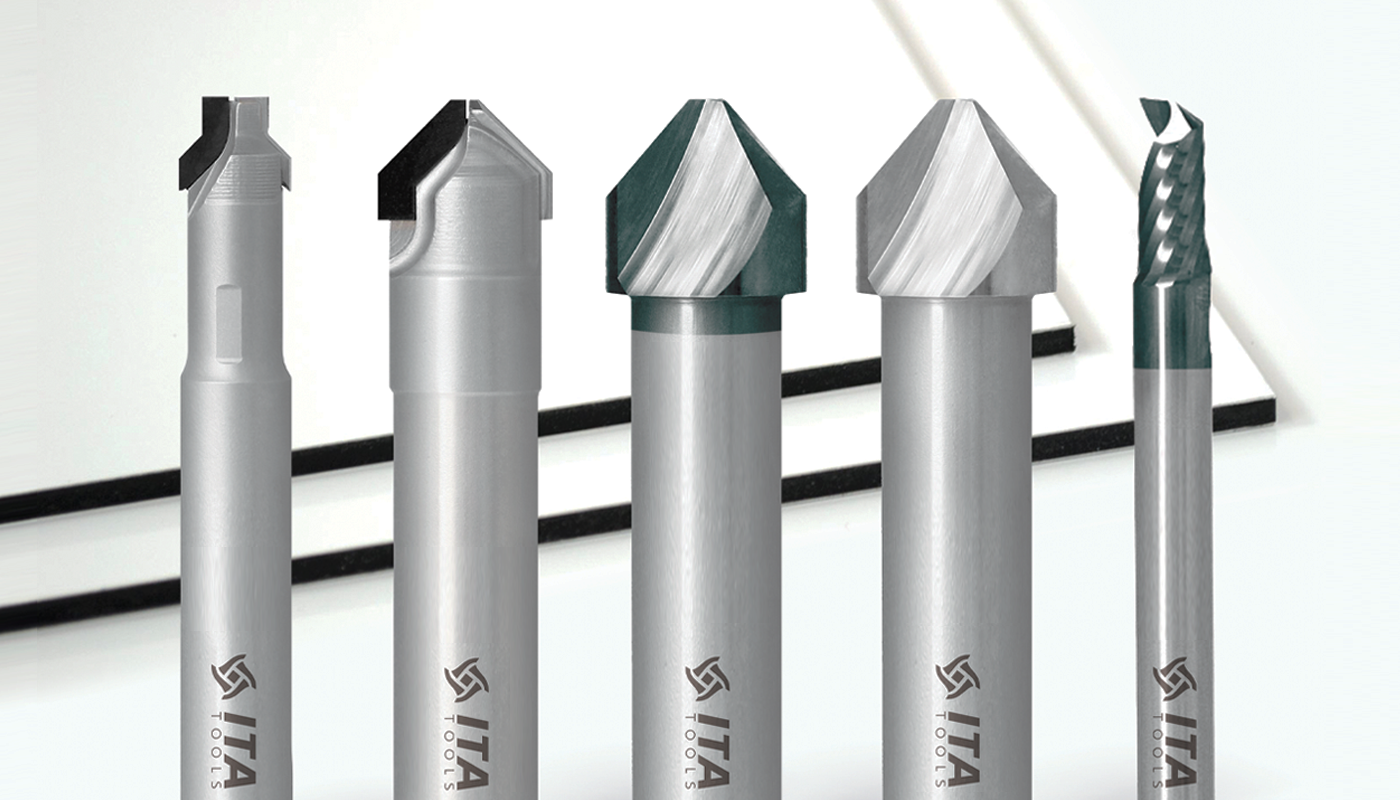

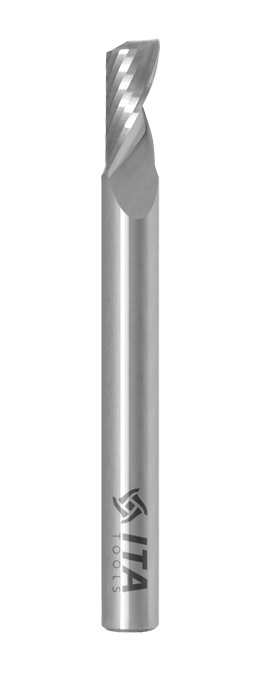

The best solution for processing of composite materials on CNC machines are carbide and diamond milling cutters by ITA TOOLS. They guarantee efficient and effective work while maintaining a perfect cutting edge or bending of the composite panel at 90°, 108°, 135°.

A selection of ITA TOOLS cutters for machining all the most popular brands of composite panels DIBOND®, ETALBOND®, ALUCOBOND® of plastic or non-flammable mineral core involves the selection of a suitable tool and the parameters for the work.

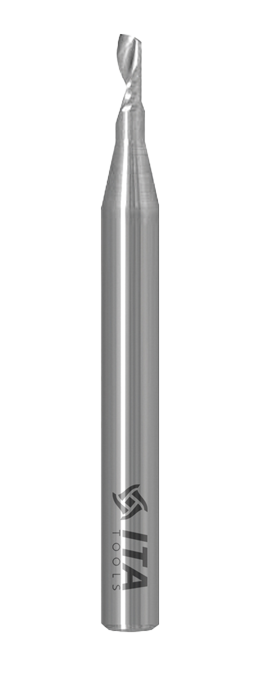

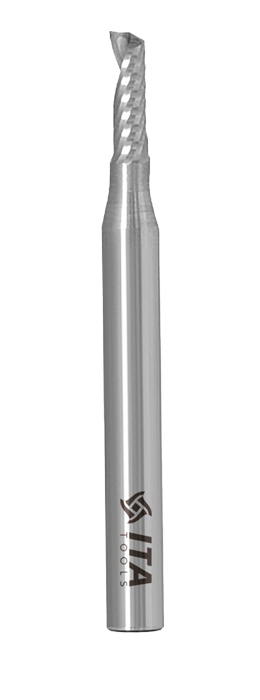

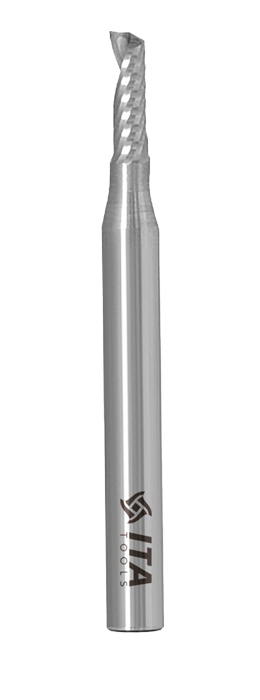

ITA TOOLS VHM series for cutting with the option of HC coating, which prevents material sticking and increases tool life.

Cutting

Turnover: 18,000 - 24,000

Feed rate: 3 - 6 m/min

Turnover: 18,000 - 24,000

Feed rate: 3 - 6 m/min

Turnover: 18,000 - 24,000

Feed rate: 3 - 6 m/min

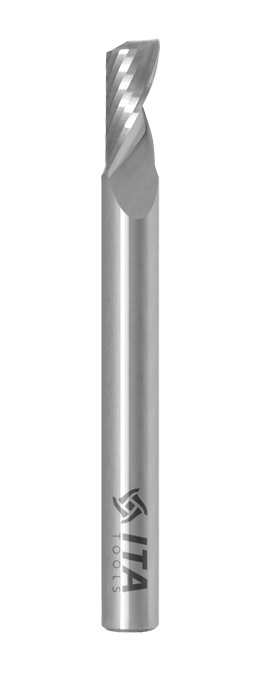

Bend

90-degree bend

Turnover: 20,000 - 22,000

Feed rate: 4 – 8 m/min

108-degree bend

Turnover: 20,000 - 22,000

Feed rate: 4 – 8 m/min

135-degree bend

Turnover: 18,000 - 22,000

Feed rate: 4 – 8 m/min

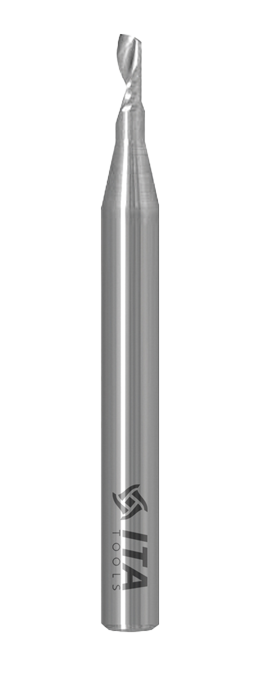

Recommended tools made by ITA TOOLS in the PCD version for cutting and 90-degree bending of type A2 material with a non-flammable mineral core:

Cutting

FDT.12.006.12.0SR

Cutting, slicing

Operating parameters: speed 18 000 - 22 000 feed rate 4 - 6 m/min Ap-max

Bend

FDH.18.007.16.0SR

90-degree bend, 3 mm bend

Operating parameters: speed 16 000 - 20 000 feed rate 4 - 8 m/min Ap-max

It is also worth remembering that in order to process materials such as AL / PE / AL composite panel and A2 composite panel effectively and efficiently, it is necessary to use CNC machines from leading manufacturers - the KIMLA®, SERON®, PGCNC®, INFRAFORM®, AXYZ® czy AES®.

Wide range of composite materials and tools dedicated to their processing, it is possible to select a product perfectly adapted to the requirements of our customers. In case of doubt, we encourage you to Wide range of composite materials and tools dedicated to their processing, it is possible to select a product perfectly adapted to the requirements of our customers. In case of doubt, we encourage you to contact our specialists, who will be happy to answer all your questions. with our specialists, who will be happy to answer all your questions.