Diamond cutters are the best choice when it comes to machining hard materials (wood-based materials).. In our range you will find a wide selection of diamond cutters, which are characterised by an extremely high abrasion and overheating resistance. The hardness of diamond inserts in relation to carbide is significantly higher, which is particularly important when machining wood-based materials.

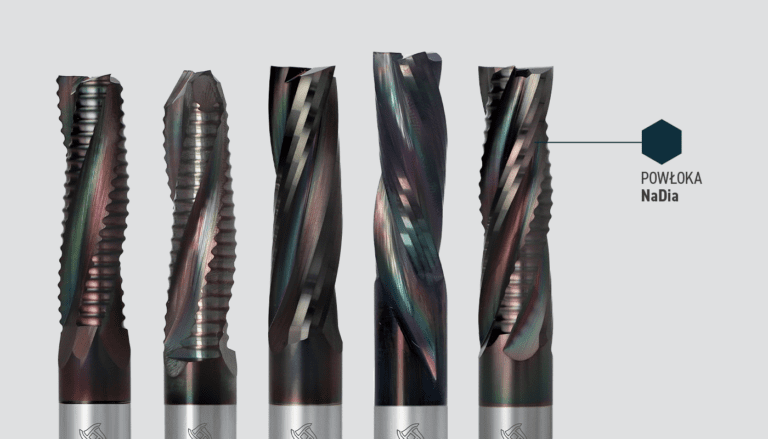

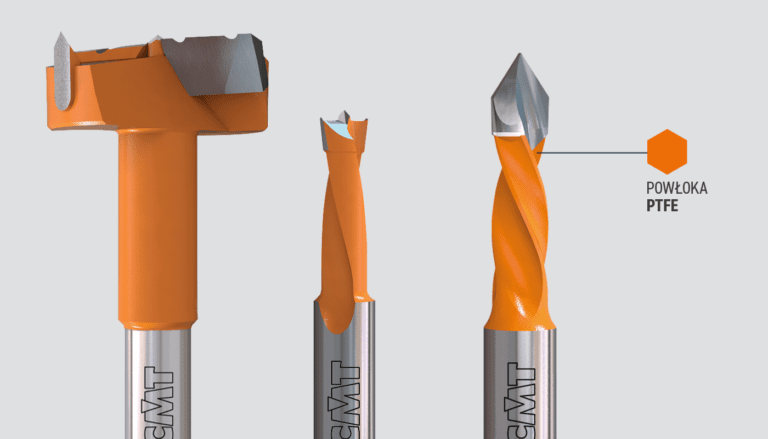

A wide range from ITA TOOLS

Depending on the application, the parameters used and the material to be processed, we offer grooving, formatting, nesting and profile milling cutters. Each cutter, thanks to its high precision, allows for efficient cutting and milling of wood-based materials such as chipboard or MDF.

The cutter bodies are made from a variety of materials: steel, tungsten carbide, Densimet, which has an impact on the hardness and service life of the tool. For small cutter diameters, harder materials are recommended.

All diamond cutters are made at equal axial angles. The larger the angle, the more aggressive, the better the material finish.

Diamond Router Bits - characteristics

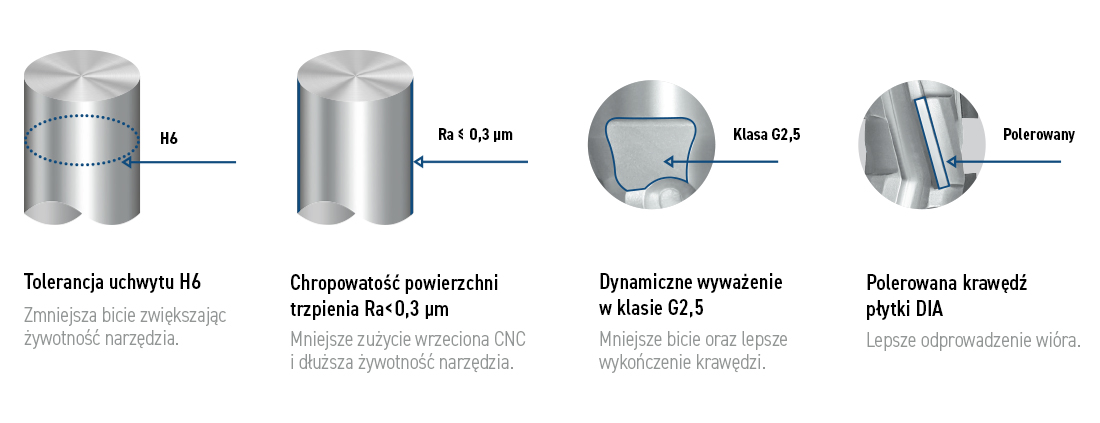

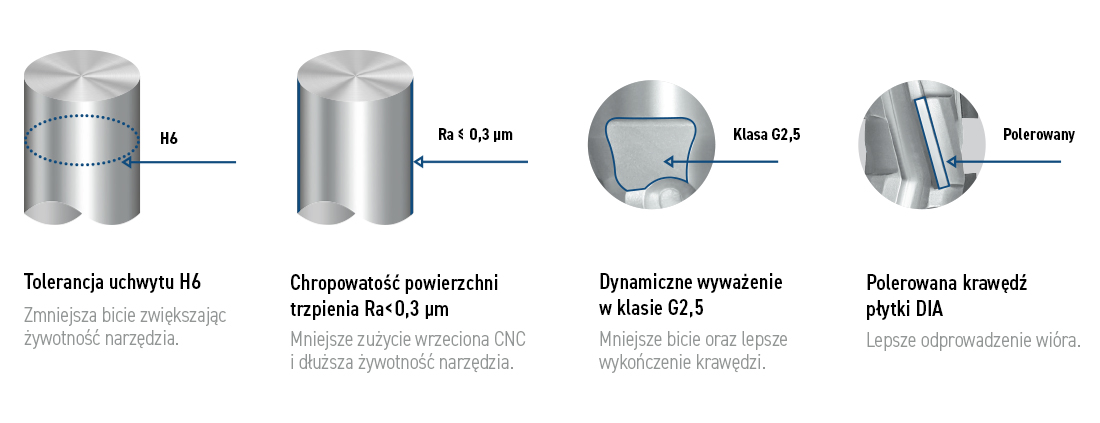

High precision is the greatest advantage of our brand of diamond cutters. We offer diamond cutters made with a roughness Ra ≤0.3 μm and a shank tolerance of h6.

- Roughness Ra ≤0.3 μm (micrometres) finish grinding, i.e. body smoothness.

This parameter affects the quality of clamping in the chuck. When the mandrel is clamped in the chuck, the clamping force will translate parallel over the entire surface of the mandrel.

- Shank tolerance in accuracy class h6.

This characteristic means that the shank of our cutter and measuring the diameter at any point, the difference in diameter will be no greater than 0.011 mm. When the shank is clamped in the chuck, the clamping force will translate parallel across the diameter of the shank.

- Dynamic balancing of each cutter in G2.5 class.

The extremely high balancing tolerance gives stability to the work, eliminating the slightest vibration at high speeds. For ITA TOOLS milling cutters, the under sink on the cutter body is characteristic. We do not drill holes in the shanks, as most manufacturers do.

How to manage Diamond Router Bits?

In order to use diamond tools effectively, a well-adapted tool design for the type of material being machined will play a key role. Precise working parameters, such as the correct feed rate and speed, are also important and have a direct impact on the efficiency of the machining process. It is also worth paying attention to the quality of the material being machined, as this affects not only the tool life, but also the quality of the final product.

It is also important to choose thermal or hydraulic chucks, which effectively reduce the risk of unwanted vibration when working with a diamond cutter. By using the right chucks, it is possible to achieve a higher level of precision and stability in the machining process, which translates into better results. It is therefore worthwhile, in addition to the tool itself, to focus on a comprehensive approach to the diamond milling process, considering both its design, and working conditions.

When you choose diamond cutters from ITA TOOLS, you are guaranteed the highest quality finish on your workpiece. Skontaktuj się Contact us for more information and to find out about the entire cross-section of diamond tools on offer.