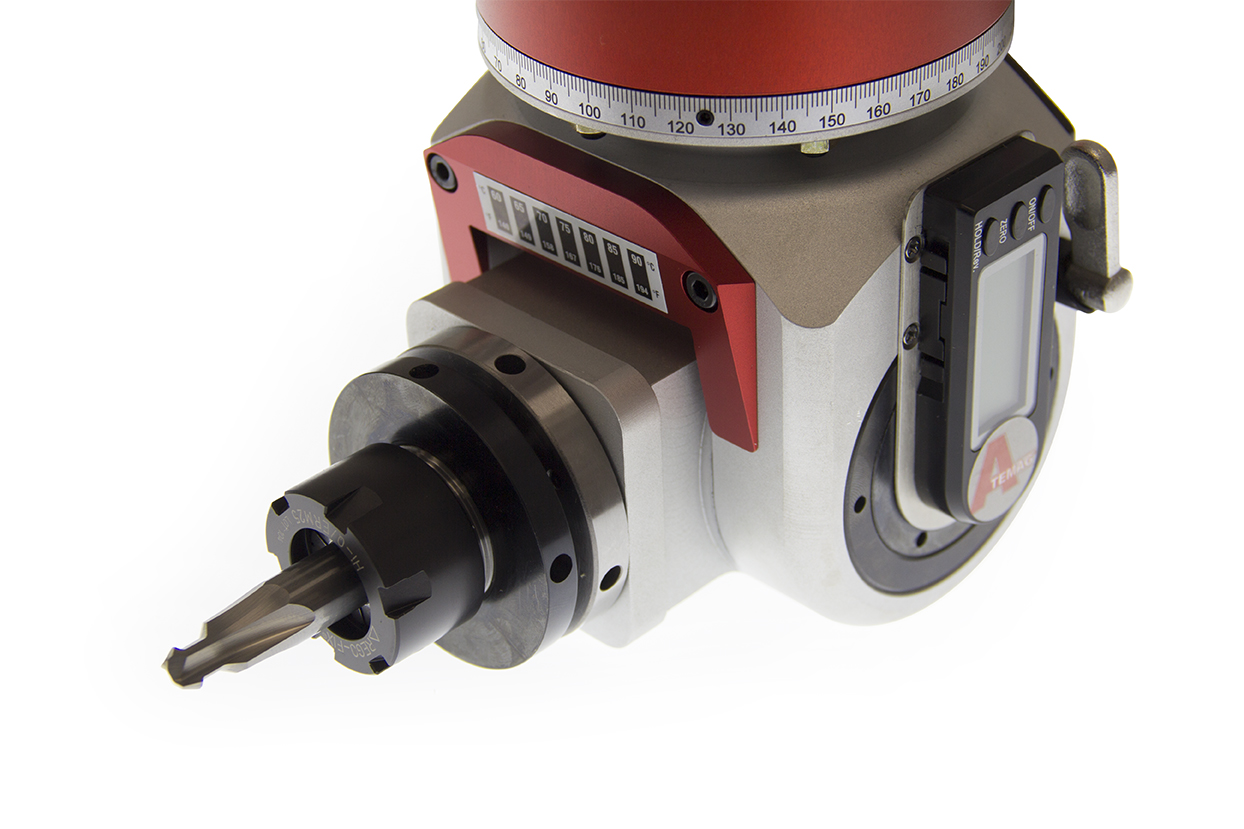

The emphasis on product quality and reliability has allowed the German company ATEMAG to secure a strong position in the market for manufacturers of aggregates for numerically controlled machines. Find out why you should choose CNC aggregates from ATEMAG!

What distinguishes the CNC aggregates from ATEMAG?

The secret of the longevity of this manufacturer's equipment lies in the precision of its selection and careful workmanship. The components used for assembly come from local German manufacturers and are subjected to quality testing. Precisely manufactured and calibrated bevel gears - down to 0.06 mm - enable quiet operation, below 80 dB. A specialised technician assembles each aggregate. The assembly process, including measurements, is recorded on a card with an assigned serial number. This procedure makes it possible to check the history of the unit even many years after it has left the manufacturer's warehouse.

The wide catalogue range of aggregates and the ability to design and manufacture special versions ensure that the manufacturer will deliver a reliable unit that meets the exact needs of the customer.

Choose the best CNC aggregates

CNC aggregates are a small device that avoids the costly purchase of expensive five-axis machines. They create opportunities for analogous machining on existing four-axis centres with optimum efficiency.

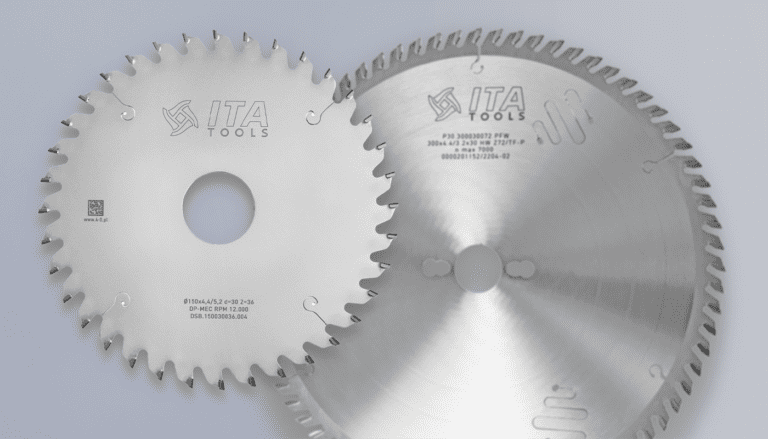

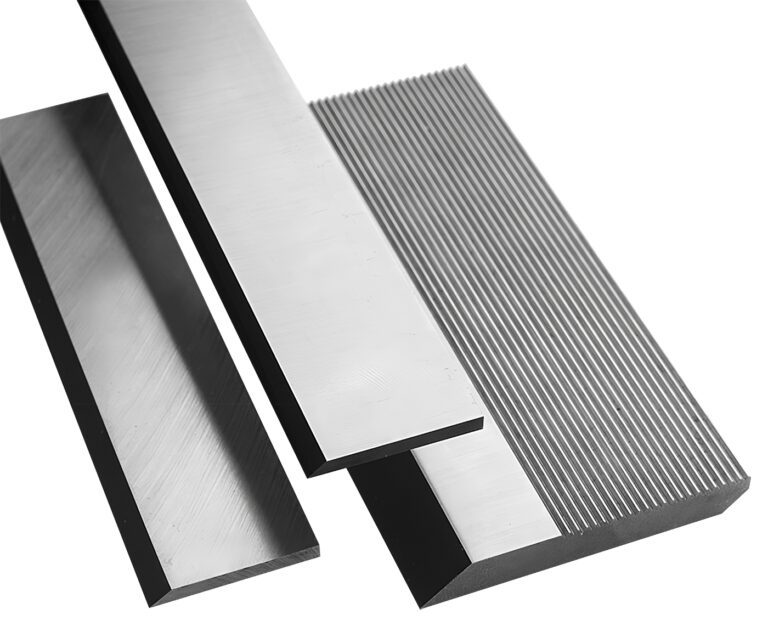

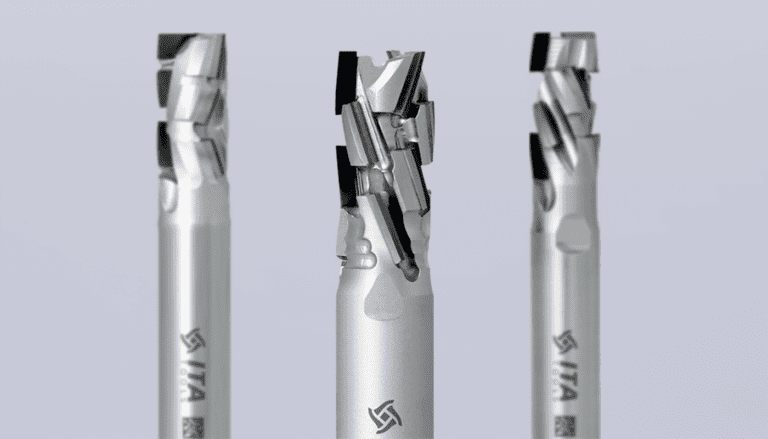

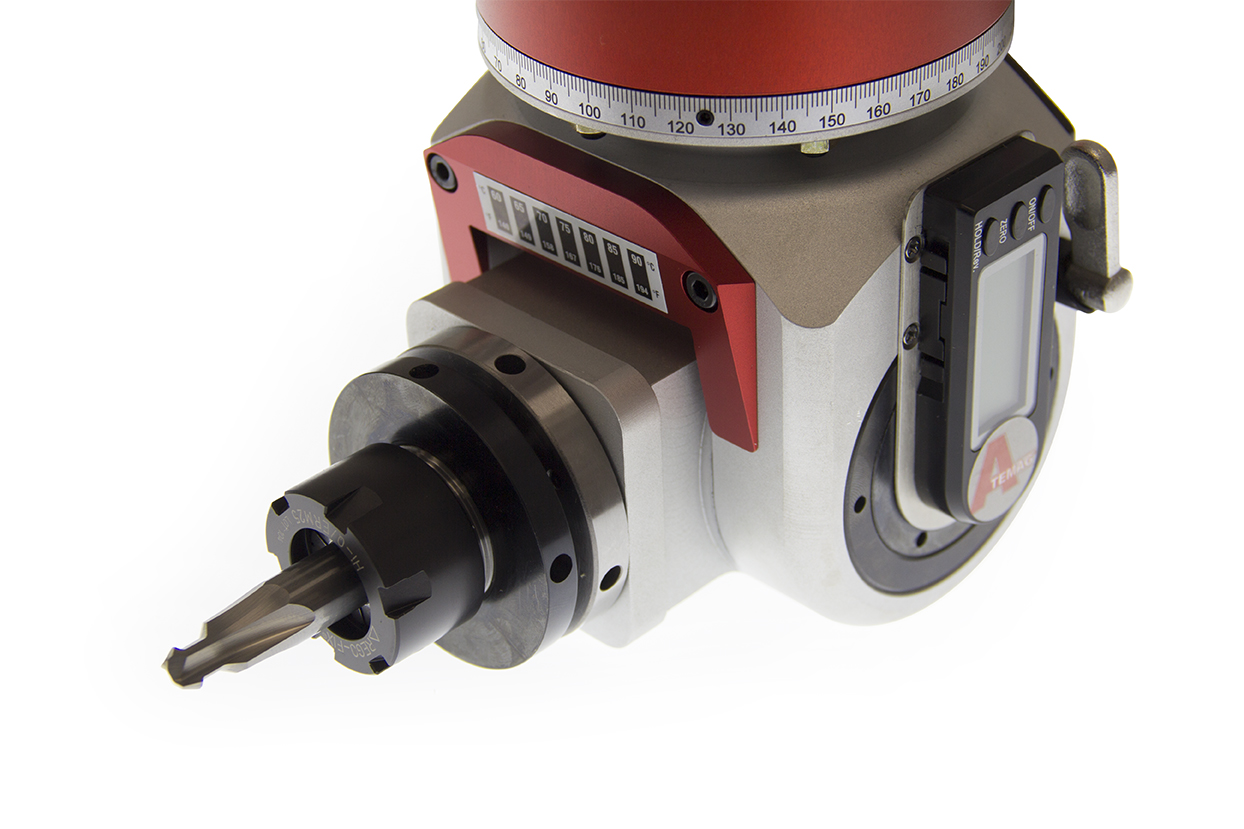

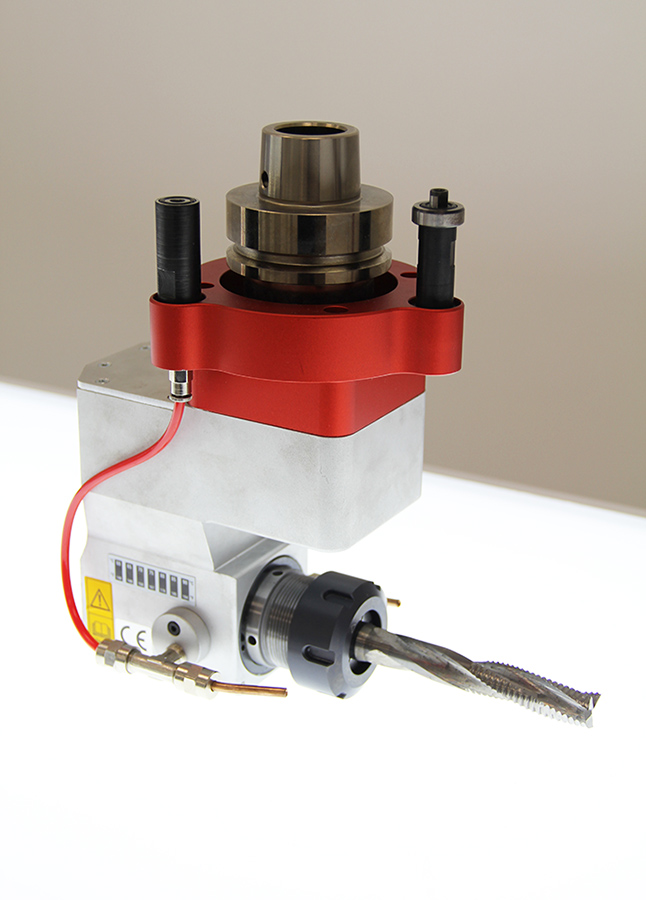

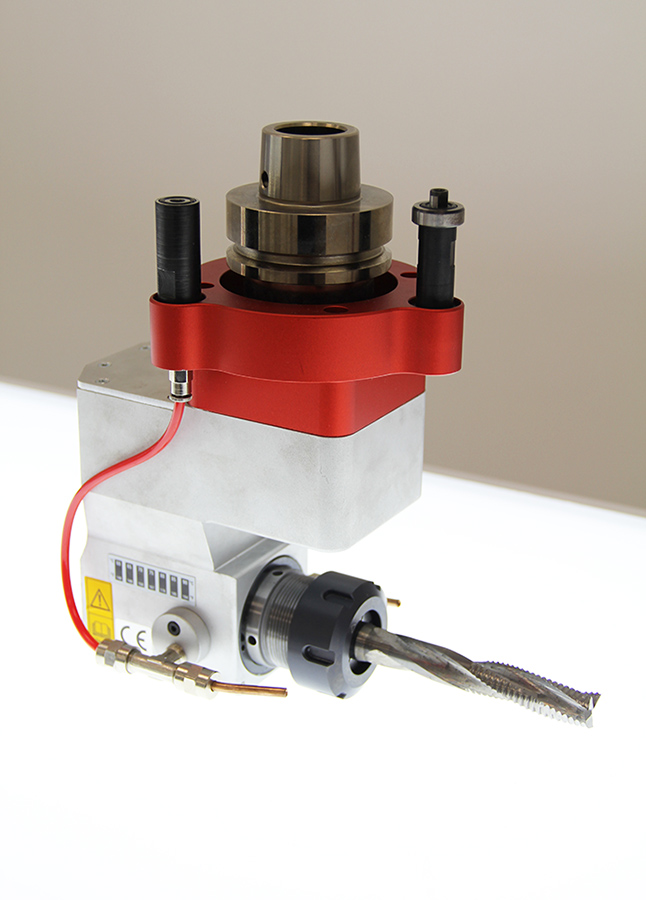

Among ITA TOOLS customers, the DUO, VARIO VISO and EXTRA aggregates from the Function Line series are the most popular. The first has two tool outlets at 90°. The Vario Viso, on the other hand, allows the working angle to be selected between -10 and 90°. The main purpose of the devices in this series is to mount drills and cutters. They are also ideal for furniture production, which uses the OVVO system. The Extra unit, on the other hand, with its "retracted" housing, allows the machining of holes for door locks and other operations requiring the use of long cutters. The SOFT-TOUCH "floating" aggregate is also worth noting. Thanks to its design, it maintains an even depth of the milled groove or drilled hole.

Horizontal milling on four-axis CNC

One of the most popular aggregates is the Extra model. It is an aggregate that creates the possibility of horizontal milling in the material. This is particularly useful when milling for a lock pocket in a door leaf. There are, of course, many other possibilities for horizontal milling, so aggregates of this type are very useful.

The Extra aggregate has two tool outputs, which guarantees the possibility of speeding up the process, as the machine does not have to take another tool from the magazine. Thanks to this solution, it is possible to make the aforementioned complete lock pocket, including milling for the so-called signboard. The Extra aggregate has a specially recessed design so that longer tools, often used in door manufacturing, can be worked with. As an additional option, two chip-removing air supply nozzles can be fitted. Precisely manufactured and calibrated down to 0.06 mm, the gears are the 'heart of the aggregates'. They allow quiet and quiet operation, below 80 dB, which is important for the working conditions, especially for the machine operator.

Contact your Atemag representative today for professional advice and assistance in selecting the right machine to meet your processing requirements.