PTFE-coated drills guarantee reduced tool heat build-up and precise holes in wood and wood-based materials. Find out what you need to know about them!

A crucial element in drilling processes in wood or wood-based panels is the right choice of tool for the material to be machined and the working parameters. More and more modern drilling machines are emerging that can drill hundreds of holes per minute. This makes it possible to increase production efficiency and produce even more parts. Drill operators want to get the most out of the machine, which is why they are keen to use high-quality drill bits. Companies therefore choose tools that not only last a long time, but also produce precise holes.

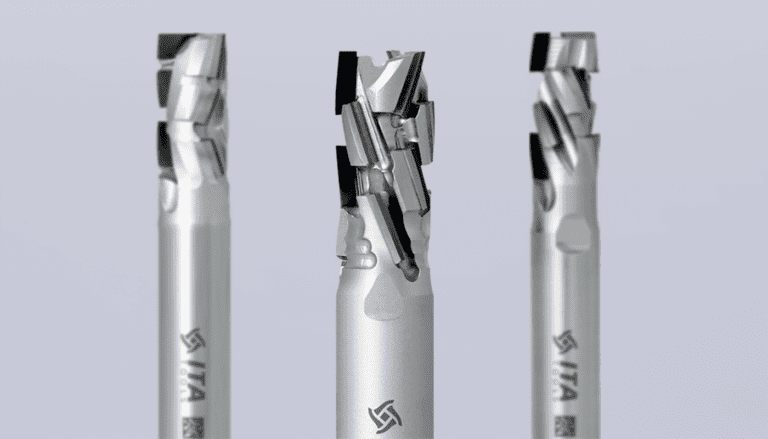

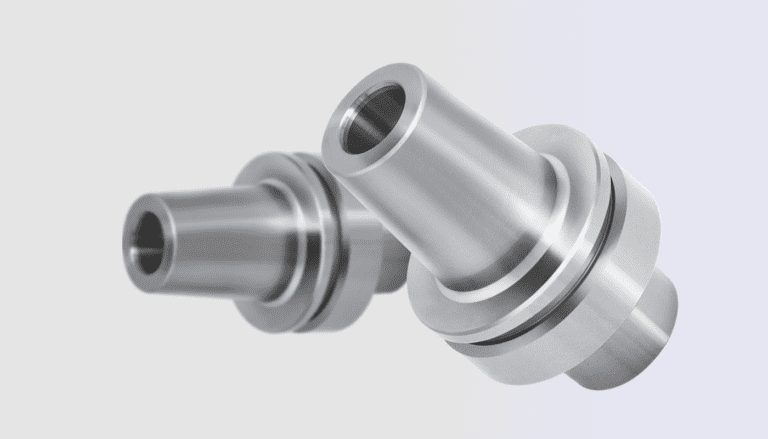

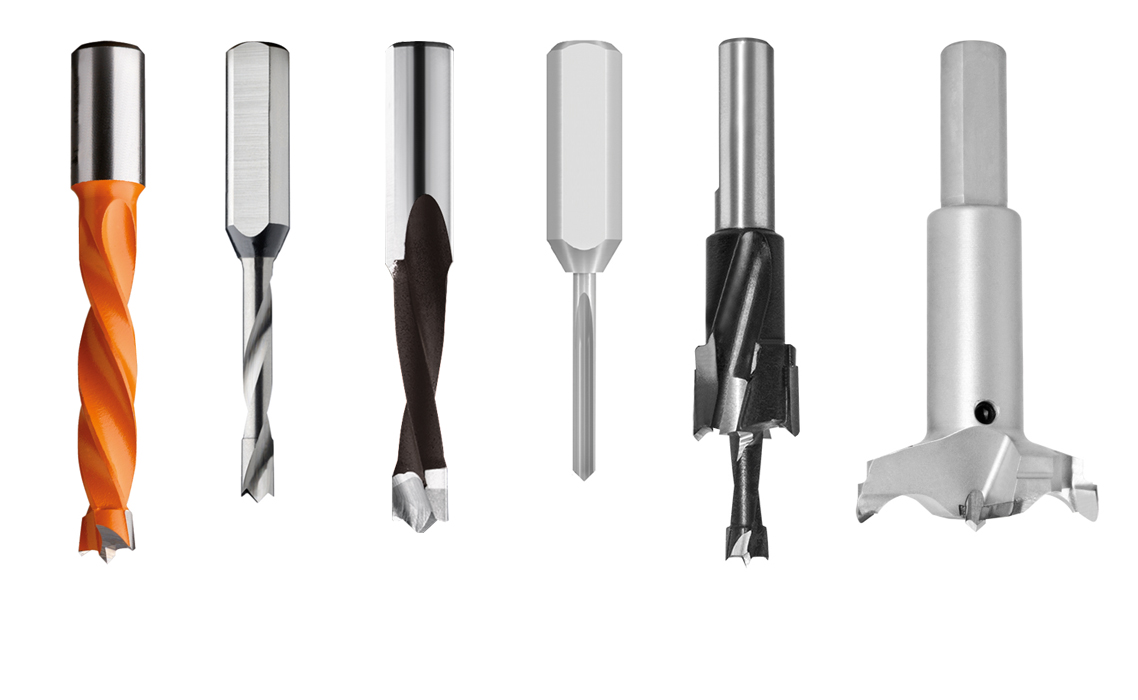

To meet the high expectations of its customers, ITA TOOLS offers a wide range of different types of drill bits and drill adapters.

What are the advantages of PTFE coating?

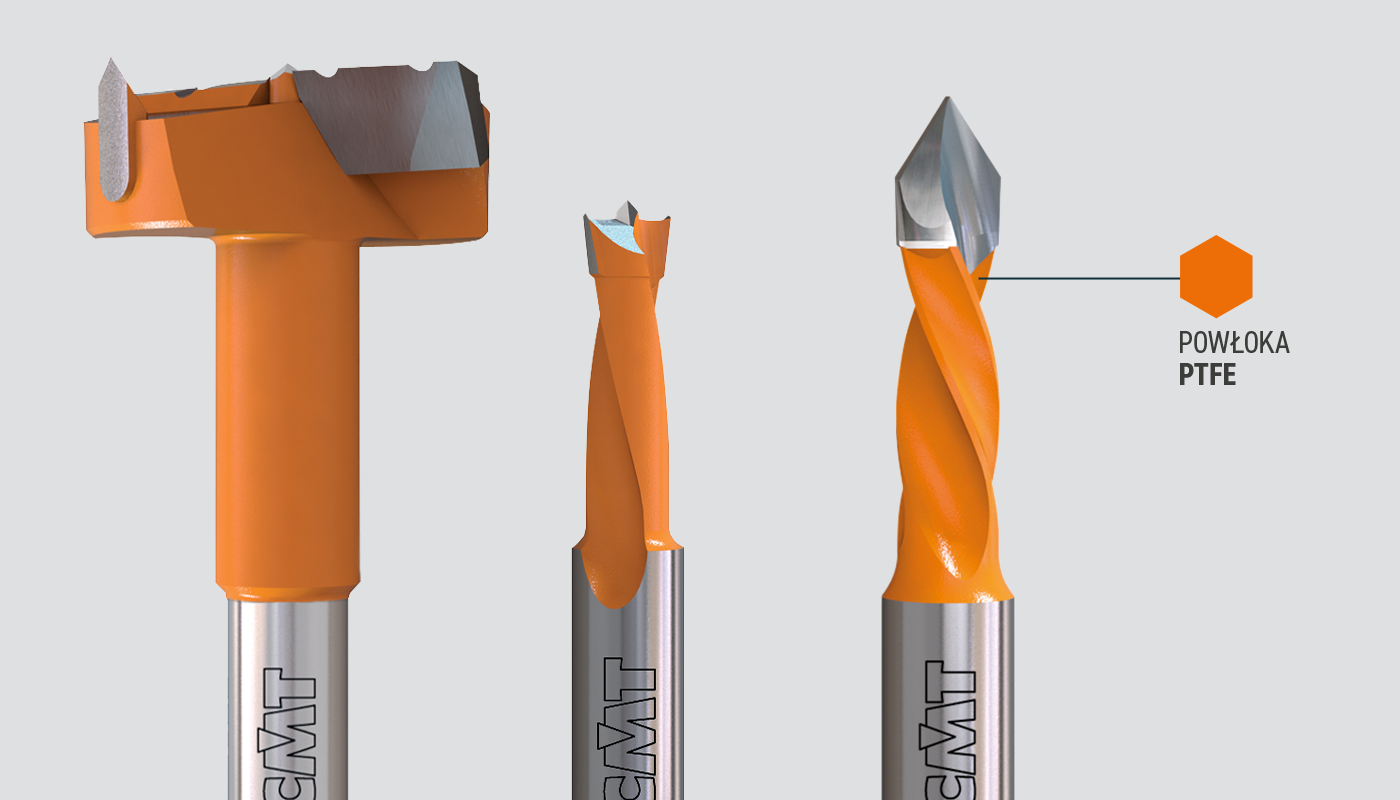

The tools we offer are made by CMT, the Italian leader in woodworking tools. CMT's drills have an accuracy class of G7, which guarantees an accurate, dimension-holding hole.

Unlike common drill bits, which are coated with an ordinary varnish, CMT drill bits are coated with a special PTFE coating. This reduces chip adhesion and reduces heat build-up in the tool. Manufacturers of high-end drilling machines also recommend that precision-made tools are used on their machines.

CMT drills - wide range from ITA TOOLS

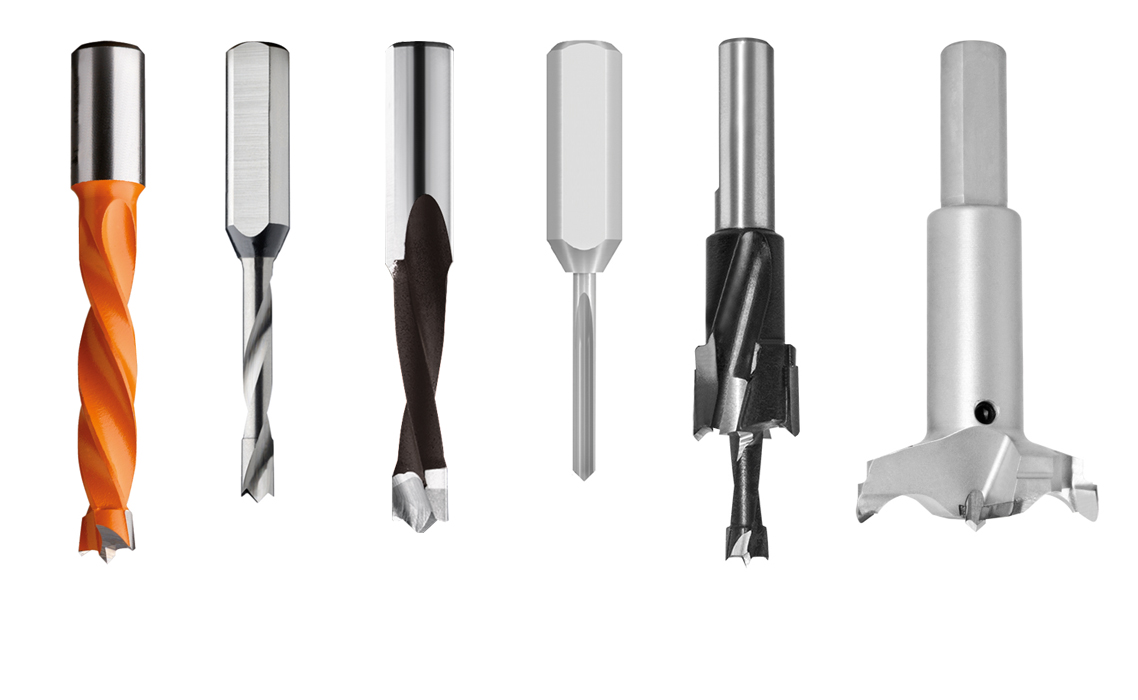

Among the wide range are universal drills, which have a clear guide pilot. They can be used primarily for wood, but also work well in wood-based materials.

The next group are the EXTREME drill bits, which have a special blade geometry designed for drilling into particleboard, laminated board. The special arrangement of the guide blade and the notches arranged at a negative angle avoids splintering of the laminate when entering the material.

Another group is monolithic tools, which are made entirely of tungsten. This guarantees a high rigidity of the tool and an increased service life, which allows for increased production efficiency. Another important group are diamond drills, which have a lifespan several tens of times longer than that of widia. Tools with diamond blades are most often used as can drill bits. New to the range are straight drills, which can operate as both left- and right-handed drills.

An important part of the range is the special tools that CMT manufactures to individual customer requirements. If you are looking for the best drill bits for your business, contact our representative or check out our offer today.