To get the most out of your diamond cutters, it is important to make sure you have the right tool holder. How do I choose the right toolholder for my cutters?

Manufacturers of CNC machines often introduce the latest developments to further improve and speed up production. It is therefore important to choose the right tooling and fixtures to maximise production speed. ITA TOOLS has a range of tools that allow very high feed rates to be achieved while maintaining a smooth edge on the workpiece.

Best tools for CNC machines

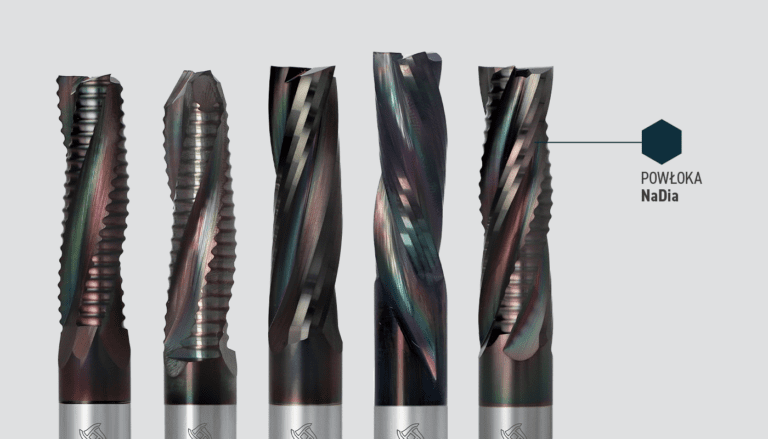

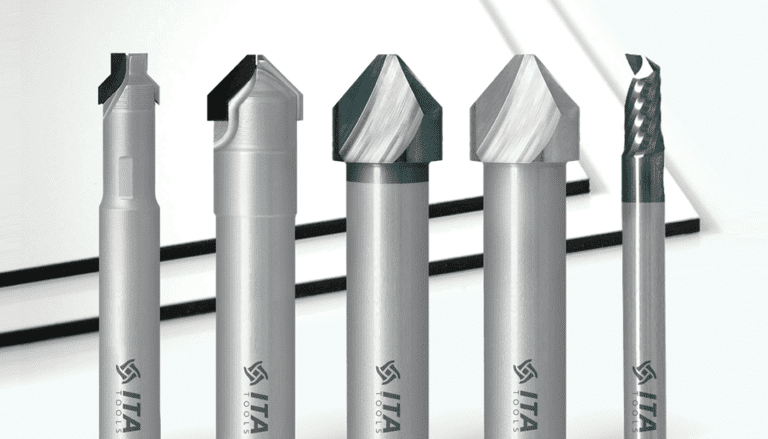

One of the best tools of its kind is the DTI series diamond cutter. Its blades are set at a very aggressive angle, which guarantees a perfect edge finish, even on demanding materials such as paper- or foil-covered board.

Another high-performance tool is the DTM series cutter, which has been specially designed for the nesting process conducted at high feed rates. In order to take full advantage of the capabilities of this type of tool, care must be taken to ensure a suitable toolholder. The entire material machining process is very much influenced by the correct toolholder on the machining centre. It affects the quality of the machined edge finish, the machining parameters and, last but not least, the life of the tool.

What makes the "TERMO" cutter holder special?

The traditional nut-and-sleeve chuck is the most common solution, but more customers are opting for thermo clamps.

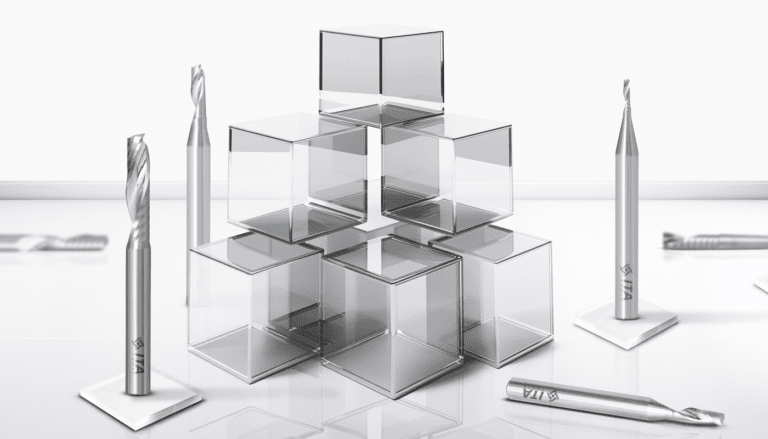

The thermo chuck is a solution that offers many more advantages than the classic chuck. First, the thermo chuck eliminates tool run-out. It has no sleeve or nut and the principle of the thermo chuck is amazingly simple. The seat in the chuck is heated by induction. The rapid rise in temperature causes a minimum expansion of the steel, allowing the tool to be inserted into the chuck. Later, the steel contracts, clamping evenly on the tool. This allows for a high degree of rigidity.

The "TERMO" cutter holder has many more advantages than conventional holders. The absence of a bushing and nut means that we have virtually eliminated the problem of tool run-out. This has a direct impact on the tool life and its working capacity. The lower the run-out, the faster the material can be machined while maintaining a perfect edge after milling. The absence of a clamping cage excludes the deposition of dust particles, which is often the cause of tool breakage.

The lack of a nut is also a reduction in the diameter of the part of the chuck where the tool is located. This allows the operator to carry out a variety of projects, especially on five-axis machines. Our thermo chucks also have a high clamping force of 1,300Nm, which excludes the possibility of the tool rotating in the chuck.

Thermal clamps in your business

Thermo chucks are increasingly being used by customers to take full advantage of their tools and extend their service life. Due to the high level of interest, we have introduced the following to our product range handles, the fitting of tools in them free of charge on a special machine and the provision of a sharpening service for tools fitted in thermo chucks.

See the process of mounting tools in thermo holders!