HPL is a laminate produced under high pressure, created from several or more layers of paper impregnated with resin. What distinguishes this material and what should be kept in mind when processing it?

Benefits of HPL

Due to its properties, HPL is ideal as a replacement for wood or metal. It is weather-resistant, does not absorb moisture, and is distinguished by its durability and resistance to chemical and biological substances. HPL is used in both internal and external structures. They are used as a structural element in balustrades, fences, facades, toilet cubicles, countertops, changing rooms or lockers.

Which tools to choose?

Due to the difficulty in machining hard materials and the associated rapid tool wear, we have developed a range of products that are ideal for machining HPL.

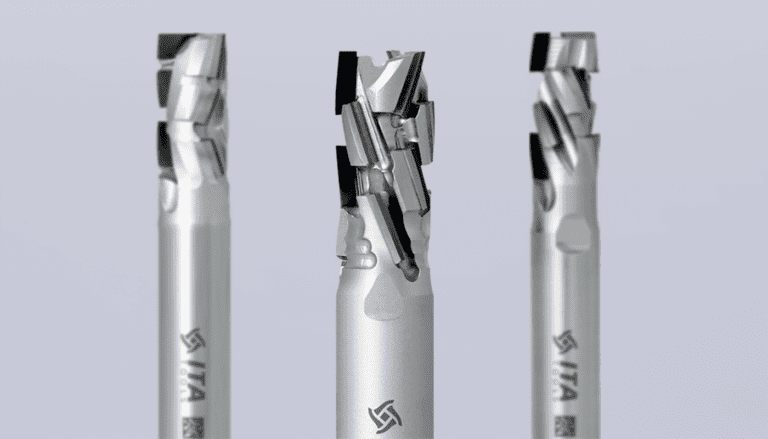

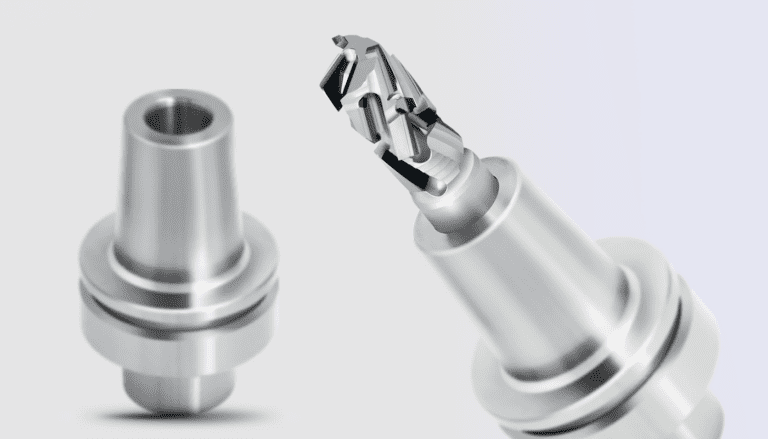

Tools manufactured by ITA TOOLS dedicated to machining HPL guarantee efficient cutting and edge finishing of the material. We offer both: VHM solid carbide cutters, VHM coated cutters and PCD cutters. Cutting, grooving, chamfering, corner radius, double radius and engraving are all variants of work that can be successfully conducted using solutions from ITA TOOLS. Please feel free to contact us or set up a B2B account to find the right tool.

What else is worth knowing about HPL treatment?

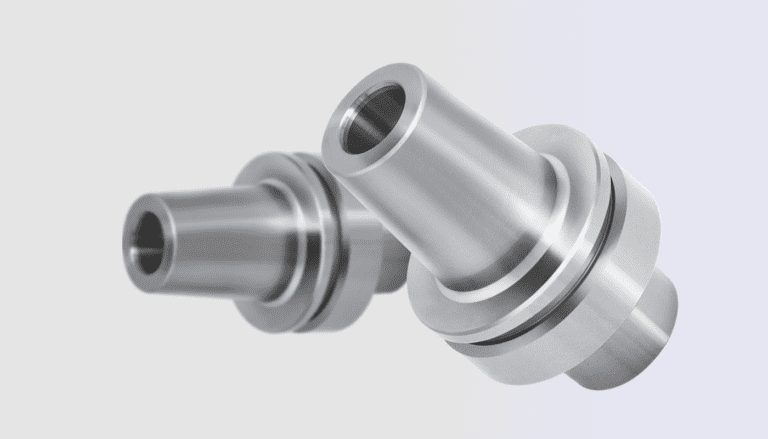

The best solution when selecting tools for HPL processing is to use THERMO holders and special coatings. These will increase tool life, reduce working temperatures, and prevent material sticking. We also recommend the use of PCD milling cutters because of their longer tool life, higher feed rates and the fact that there is no risk of damage to the cutter at diameters below fi 10 mm.

With many years of experience in manufacturing tools for machining composite materials, we know exactly how to select the best tools. By choosing ITA TOOLS products, you are guaranteed the best results when working with the tool. Contact us today.