Nesting is a technology that involves the rapid cutting of material using milling tools on a single CNC machine. How do you choose the right router bits for nesting and what distinguishes the DTM series from ITA TOOLS? Here are some tips!

Co warto wiedzieć o procesie nestingu?

The technology for fast cutting of wood-based materials on CNC machines using burrs with a special design is becoming increasingly common. This method is primarily used for cutting curved, irregular shapes, often found in upholstered furniture, but not only. The speed of the process, the very low material waste and the omission of cutting on a panel or format saw mean that the nesting process is also gaining recognition among furniture manufacturers of all kinds.

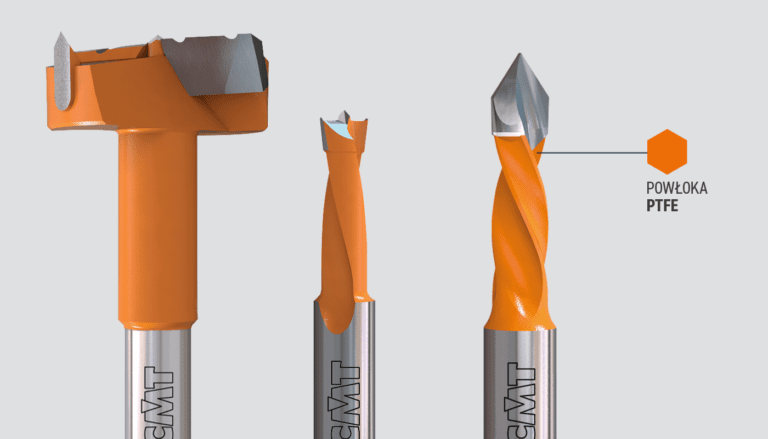

When cutting the material, the tool works below the bottom edge of the work material, so a backing plate into which the router bits are slightly recessed is necessary. Every cycle, the backing plate is planed, i.e. aligned with specially designed router bits with large diameters. Such router bits can have either carbide or diamond interchangeable blades. Both types can be found in the standard ITA TOOLS range.

The right choice of picks step by step

Every nesting process begins with the selection of a quality tool. The right router bits should be selected both for the material to be machined and for the operating parameters of the CNC machine. ITA TOOLS, based on its many years of experience in the carpentry and furniture industry, has developed a series of DTM tools dedicated to nesting operations.

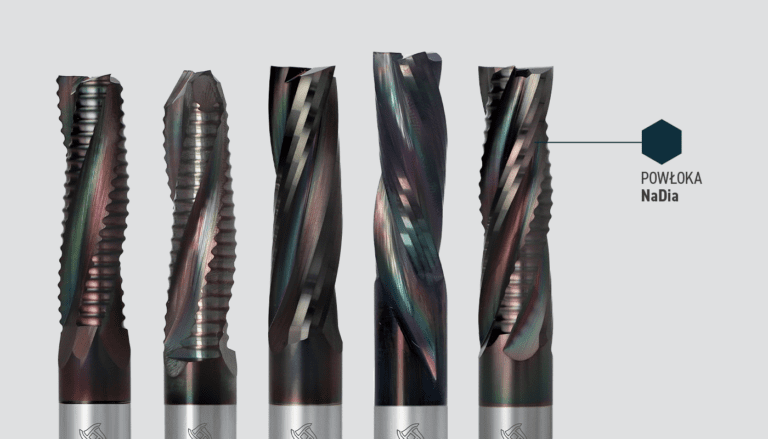

The range includes router bits with a special multi-blade design. Three overlapping blades are arranged on six spirals. Each spiral is profiled so that chip evacuation is as efficient as possible.

DTM series - try the best router bits for nesting

Given that the router bits in the nesting operation often bore into the workpiece, the face blades are also made of diamond. The DTM series router bits have a body made of steel or densimetal, depending on the working diameter. This is a very dense material that reduces the possibility of tool breakage. The reinforced material body is most commonly used for router bits with a diameter of 12 mm, the main advantage of which is low material loss.

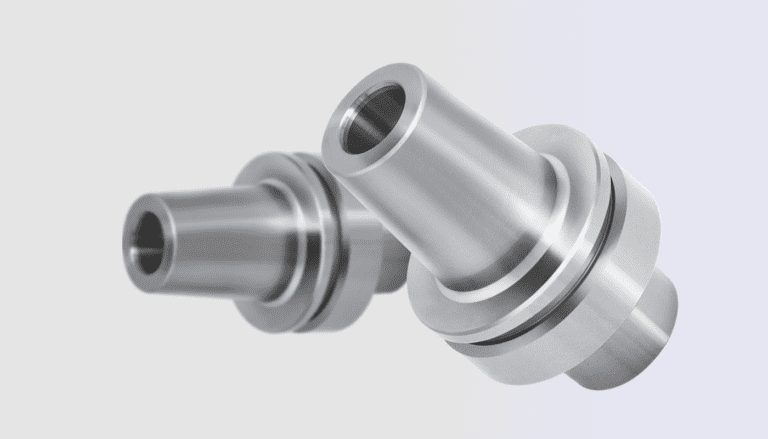

Router bits serii DTM are available with different diamond plate arrangements, positive and negative. The selection of the insert arrangement depends on the production technology of the plant. An ideal insert arrangement, combined with a reinforced body, can achieve feed rates of up to approx. 25 m/min. What should be borne in mind in order to maximise tool life and achieve better results? First and foremost, the right clamping system, such as thermo or hydro. Proper tool service is also an important aspect.

ITA TOOLS offers professional service diamond and carbide tools, ensuring very short sharpening times while maintaining the highest quality standards.