Plexiglas, also known as acrylic glass or Plexiglas, is a plastic material that is gaining popularity in both modern interior design and carpentry.

The main reasons for this interest are the versatile application possibilities and the easy processing, which can be conducted using standard power tools. In contrast to traditional glass, Plexiglas has several important advantages.

The most important of these is its high resistance to breakage, while maintaining high optical quality and excellent light transmission. In addition, Plexiglas is also characterised by significant weather resistance, making it an ideal material for outdoor applications. The ability to be easily processed allows a wide variety of cut-outs and forms to be created, without much difficulty.

Available in a variety of colours, Plexiglas is popular in the advertising industry, where it is used to produce displays, advertising coffers or trade fair stands.

Plexiglas and glass - the differences

When comparing Plexiglas with other similar materials, such as glass, there are several important differences. Plexiglass is lighter than glass, making it easier to manage and install. It is also more shatterproof, making it safer to use. However, glass can have a slightly better optical quality than Plexiglas, although this difference is minimal and usually not noticeable in many applications.

How do I choose cutters for Plexiglas?

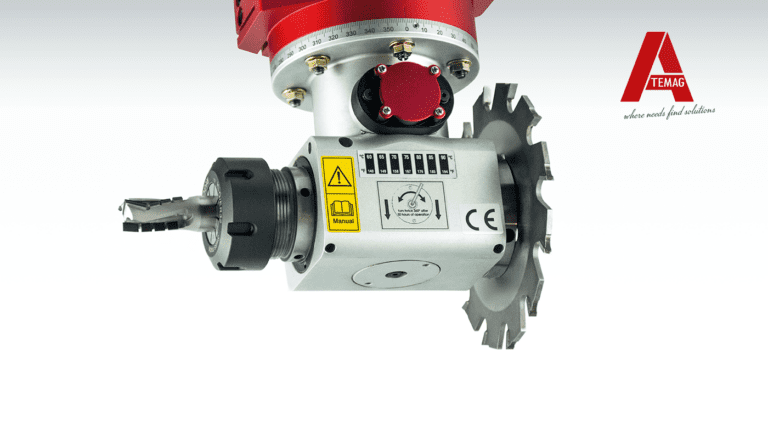

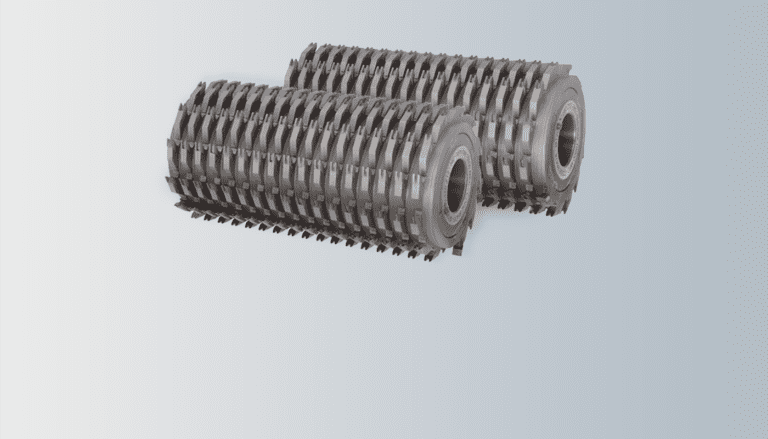

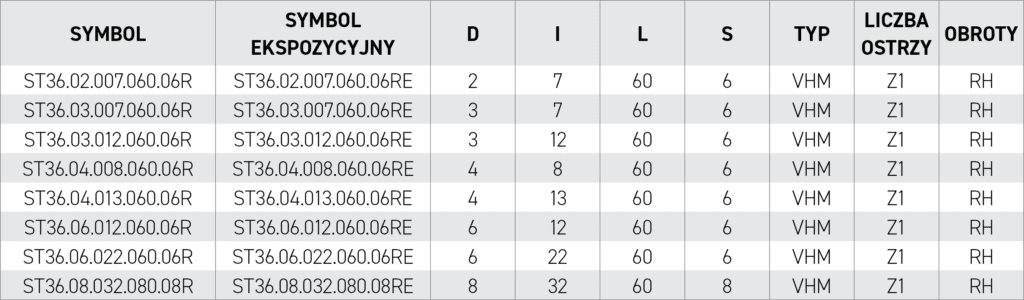

Perfectly finishing the edges of Plexiglas can be a challenge, but this problem is solved by the new ST36 range of cutters. These specially designed tools are perfect for machining polymethylmethacrylate, or Plexiglas, and other plastics.

What makes the ST36 series of Plexiglas cutters stand out?

- Single blade router bit, positive: Specially designed single-edge cutter for precise and efficient edge finishing.

- Polished chip groove: Prevents material sticking, which guarantees smooth processing and a perfect finish.

- Ejection of the Chip up This feature avoids problems associated with excessive chip retention, which contributes to clean and efficient working.

- Special type of carbide: Increased cutter life is crucial for long-lasting and efficient operation.

- Coating can be applied: The optional coating further increases the durability and performance of the cutter.

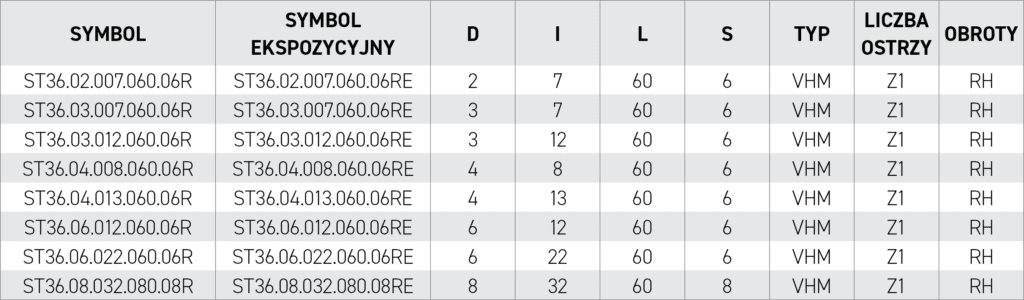

- Wide range of dimensions

Perfect material finish

To achieve the perfect finish on this material, it is also crucial to properly polish the edges to remove any imperfections and achieve a smooth, transparent surface. With polishing, the edges of the Plexiglas take on an aesthetically pleasing appearance and a better tactile feel.

Hand polishing is the simplest way to process plexiglass at home using water-based paper of various grits and polishing paste. There are also advanced polishing techniques, such as flame polishing with an oxy-acetylene torch, but these require professional equipment and experience. Care must be taken during processing to ensure precision and safety, especially avoiding edge deformation and excessive heat on the material.

Professional diamond polishing of plexiglass is the most effective, but also the most costly method to achieve a perfectly polished edge. This technique is particularly suitable for simple parts, but requires a specialised machine and a lot of money.

Best Plexiglas cutters from ITA TOOLS

When comparing Plexiglas with other materials, it is worth noting its advantages, such as lightness and resistance to breakage, which make it an extremely attractive material for many applications. However, machining Plexiglas requires the selection of the right milling cutters to significantly improve the entire process. The ST36 series is the perfect solution for those looking for tools for precision machining of polymethylmethacrylate and other plastics. With these cutters, you will achieve a perfect finish, no matter the complexity of your project.

As a manufacturer of professional cutting tools, we offer a wide range of cutters for machining composite materials. Visit our site or contact us for more information.