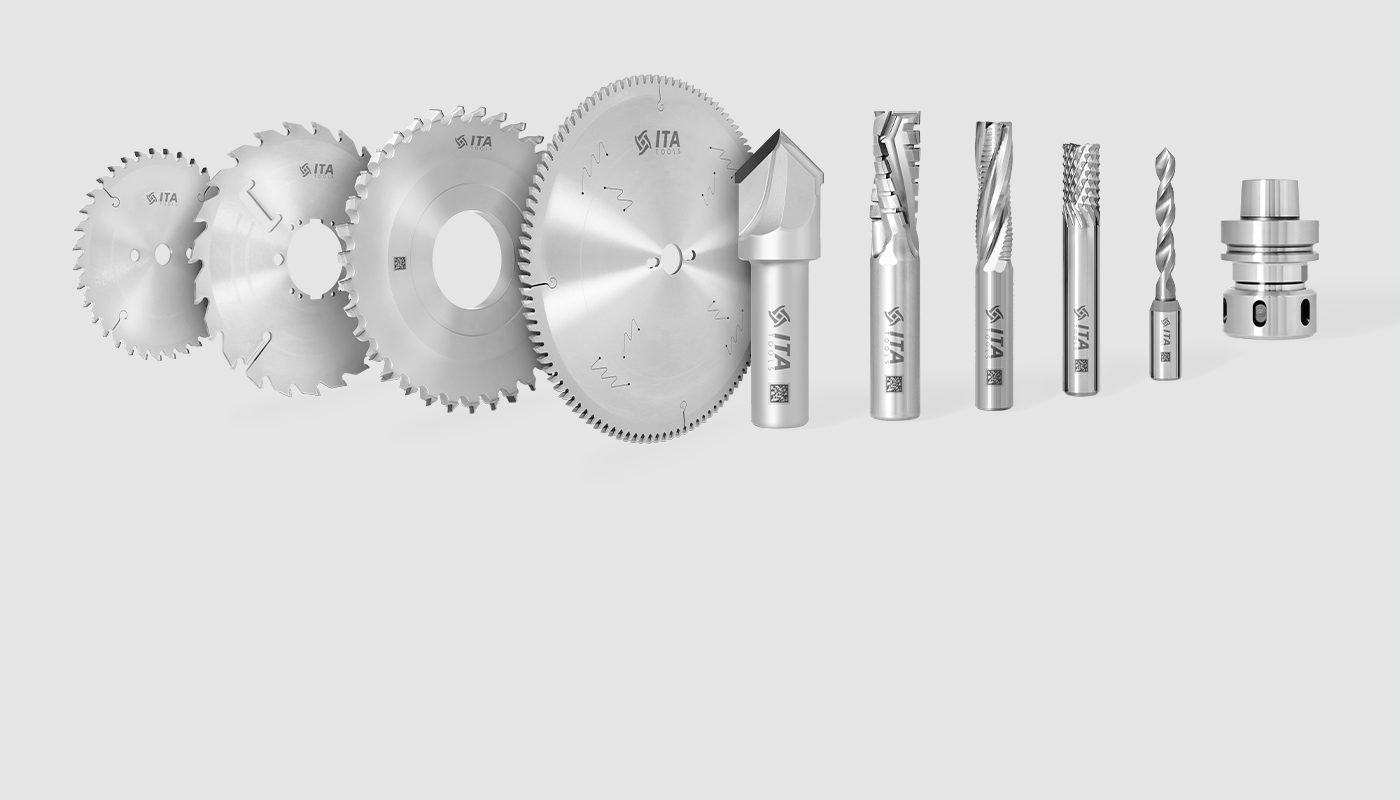

ITA TOOLS Sp. z o.o. is a dynamically growing Polish company that specialises in the production of professional cutting tools for machining wood, wood-based materials, and plastics. With one of the most modern technical facilities in Europe, we work with partners in more than forty countries.

What makes us stand out?

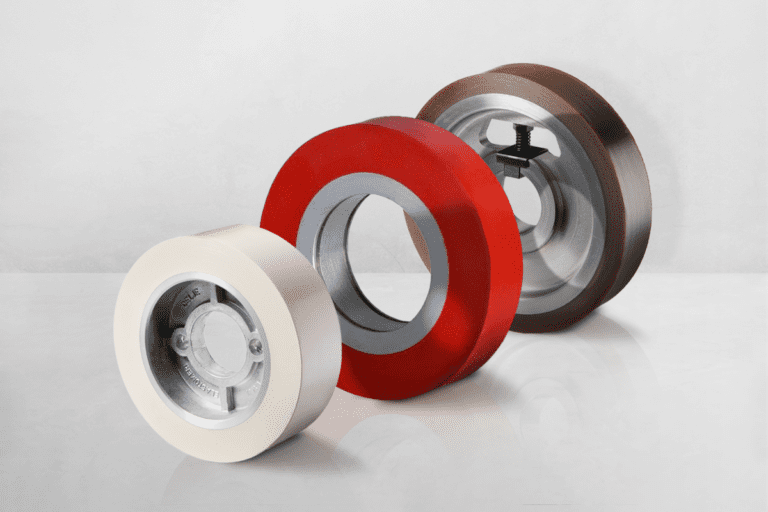

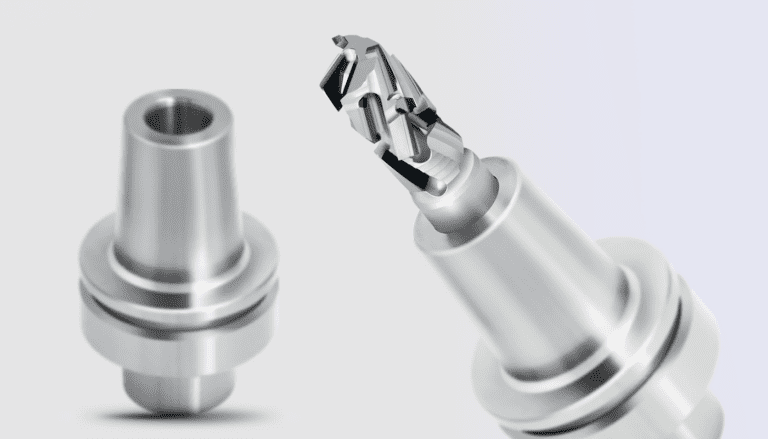

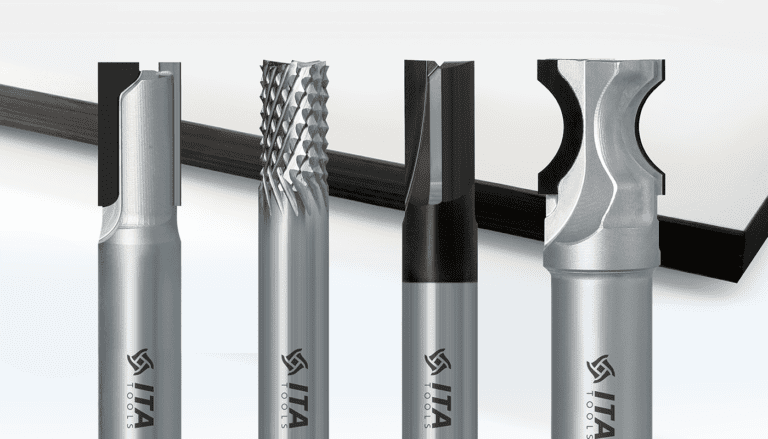

Our production centre is a state-of-the-art machine park allowing us to manufacture and remanufacture all types of DIA, HM and VHM tools. Unique technological facilities allow us to fulfil orders for products of non-standard sizes and applications.

Precision, durability, and innovation are at the heart of ITA TOOLS' success. Thanks to this philosophy, our company has recorded continuous growth, enjoying customer recognition and a strong position in the industry. Behind the excellent reputation of our tools are excellent raw materials, specialised design software and automated quality control.

In keeping with the motto #everydaybetter

Bearing in mind the dynamic changes in the market, we engage in several activities that support not only technological but also human resources development. We know that people are the essence of every company, which is why our qualified management team is constantly looking for areas of innovation, setting the direction of ITA TOOLS' development. In turn, a team of experienced employees watches over the high quality of products and provides contractors with individual support and technical advice.

For several years, we have also focused on integral development in foreign markets, cooperating with companies in more than forty countries around the world. We actively participate in trade fairs abroad, promoting the modern face of Polish industry. A multilingual team and regular training to improve our qualifications allow us to work with clients from all over the world.

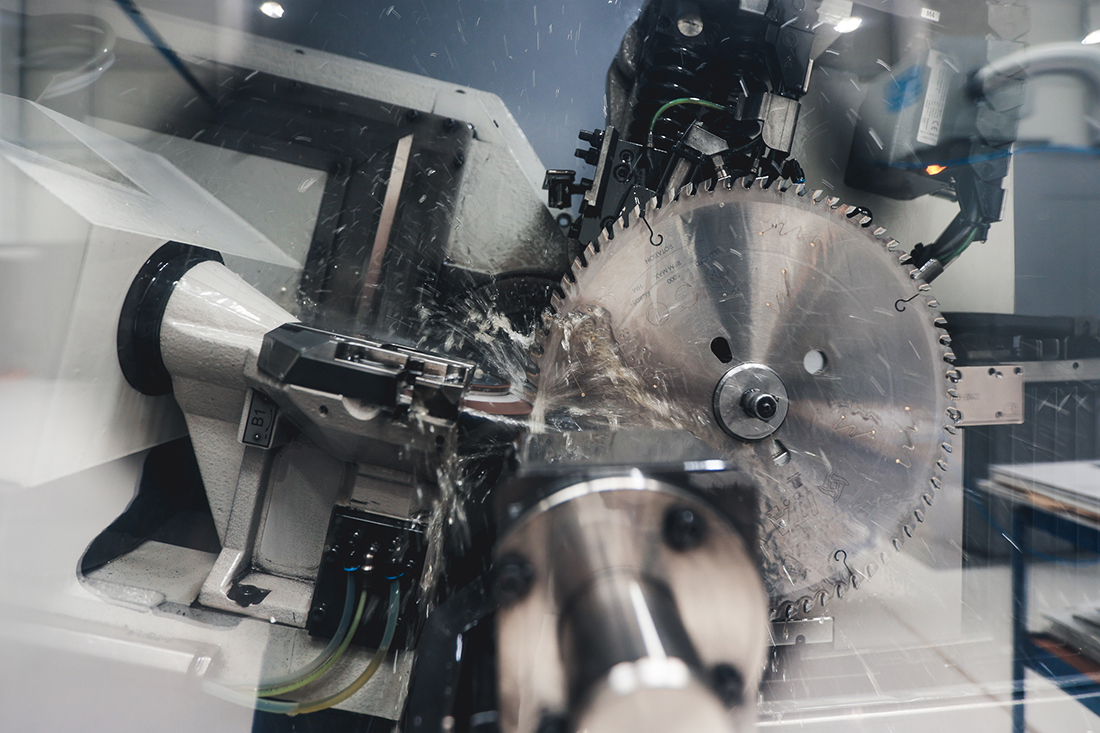

Robotisation and automation of production

The continuous implementation of new technological solutions has become an integral part of the company's development. Every day we improve and introduce innovative technologies that improve the production process. We use state-of-the-art machines with innovative systems and automatic loading by robots. This allows us to increase our production capacity, maintain high stock levels and serial production. We also use an advanced programme for production planning and monitoring. With an additional warehouse of raw materials, we can secure product availability and fixed prices.

We are also a pioneer in diamond tool sharpening technology using the laser ablation and we are the only company in Poland to offer this service to our customers. Laser ablation sharpening is a guarantee of a precise blade finish. Thanks to this technology, we provide tools with an increased service life, which ensures a better quality finish on the materials being processed.

Industry 4.0 at ITA TOOLS

We offer more than 10,000 types of tools and a modern B2B platform makes it possible to check our current stock. This allows our customers to see prices and product specifications and place orders in no time.

In line with the concept of Industry 4.0, the following has also been developed CLOUD4.TOOLS, a web-based application for tool management. Thanks to DataMatrix technology, it offers the possibility to instantly search for tools using a QR code. This solution automates the process of inspection, tool sharpening and purchasing.

Many years of experience and an ambitious view of the future are the secret of the success of the ITA TOOLS brand. Contact us and see why thousands of customers from all over the world trust us.