The main types of handles found today in the furniture and joinery industry are ISO30 cones or the HSK63F type. Find out what you need to know about them.

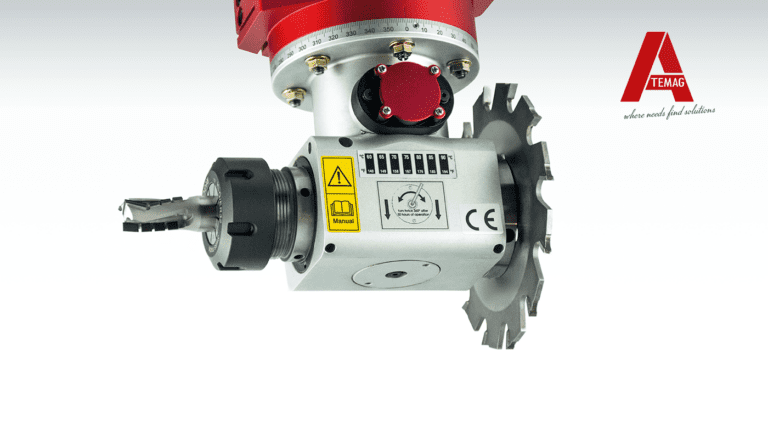

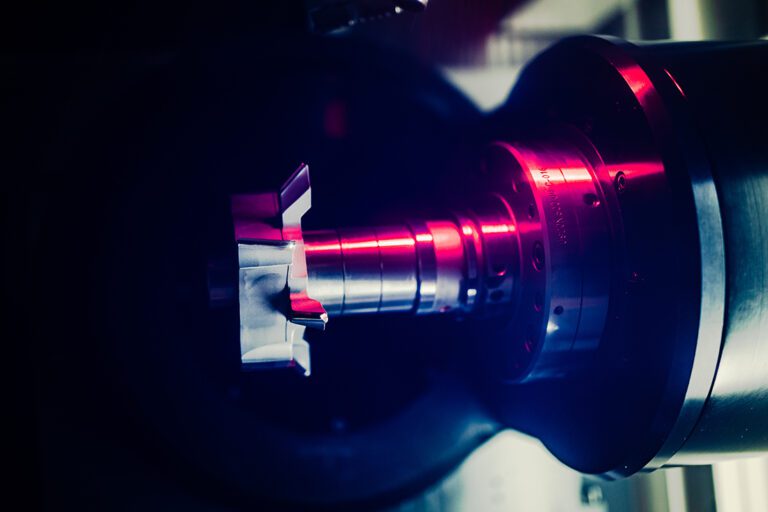

Manufacturers use them depending on the spindle that is on the machine and the type of work being done on the CNC. Modern CNC centres are equipped with chuck magazines that the machine can reach for at any time. Enough chucks equipped with the necessary tools ensures a smooth production process without having to stop the machine and change the tool every time.

What is worth knowing about handles?

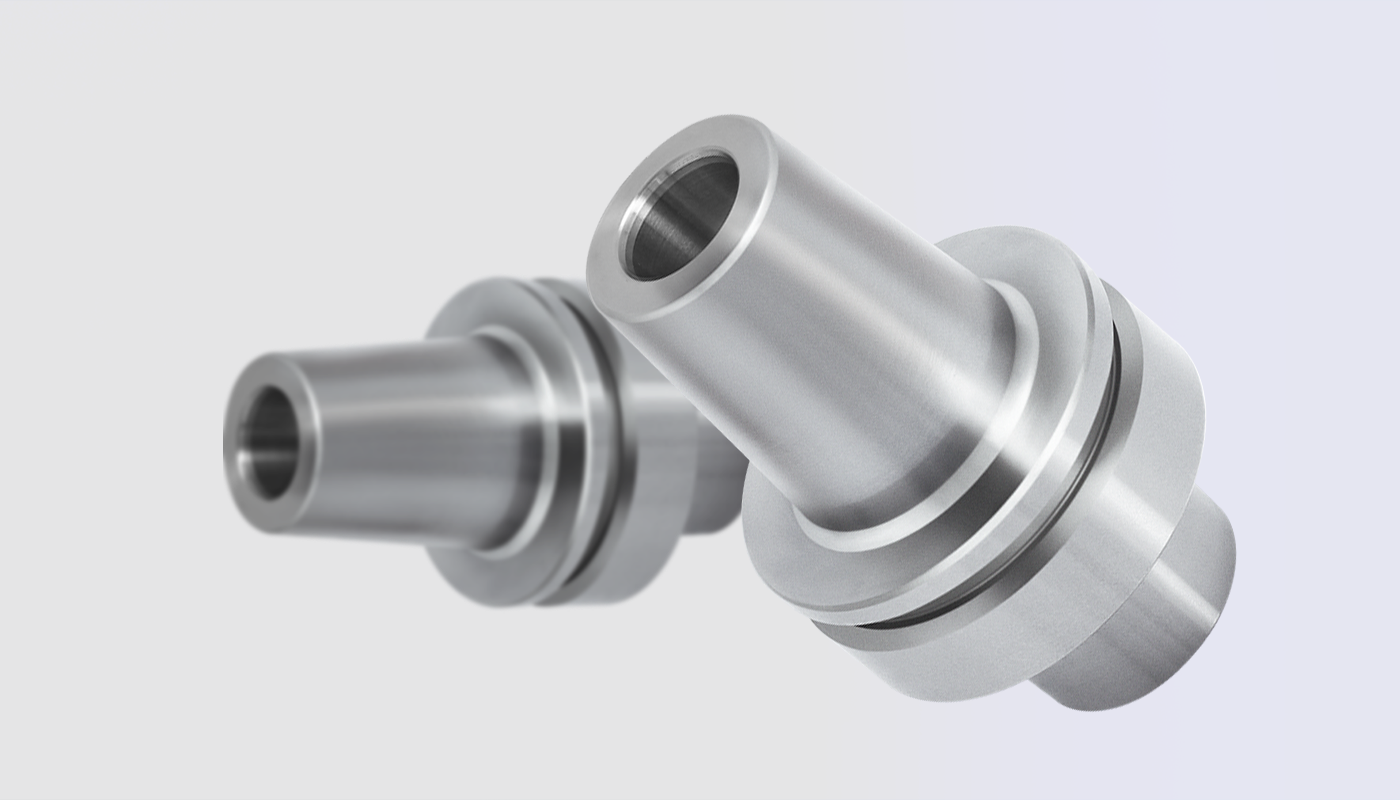

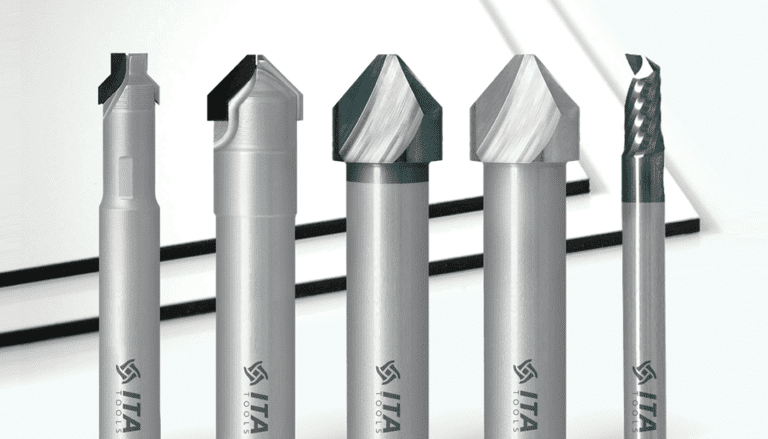

The correct clamping on machining centres has a very significant impact on the material machining process. It affects both the quality of the machined edge finish, the machining parameters, and the tool life. ITA TOOLS offers CNC chucks in both HSK63 and ISO30 versions. The most common clamping systems used on CNC machines are the HSK63F and ISO30 chucks, which are characterised by a G6.3 accuracy class as well as efficient clamping and easy handling. Furthermore, the possibility of changing the collet allows the use of tools with different shank diameters.

CNC chucks - wide range of products

Both ISO30 and HSK use collets bolted with a nut, the only difference is in the way they are clamped in the machine spindle. In addition, for ISO30 chucks, it is also necessary to select a suitable bit.

In addition to the classic chucks, with a space for a collet, there are also chucks with a shank. They allow the mounting of both cutter heads, routers bits and circular saws. An interesting group are the extension chucks, i.e. those with a longer overall length. This is particularly helpful when working on five-axis centres, where the operator often needs to perform cutter work in hard-to-reach places.

How to take care of CNC chucks?

Handles offered by us meet a range of quality standards. As a result, the CNC operator is aware that he is putting a product on his machine that will ensure its smooth and trouble-free operation. However, he or she must remember that the performance of the tool being fitted is affected by regular cleaning of the chuck seat and collets. It is also important to remember to replace the collets, which lose their elasticity over time and thus the clamping force of the tool becomes colder. In both cases, this can result in poor edge quality, tool breakage and even damage to the machine spindle.