How do you get better results when cutting chipboard and MDF on panel and format saws? The solution is a combination of HM saws with nano carbide and diamond scoring saws from ITA TOOLS.

How do you get better results when cutting chipboard and MDF on panel and format saws? The solution is a combination of HM saws with nano carbide and diamond scoring saws from ITA TOOLS.

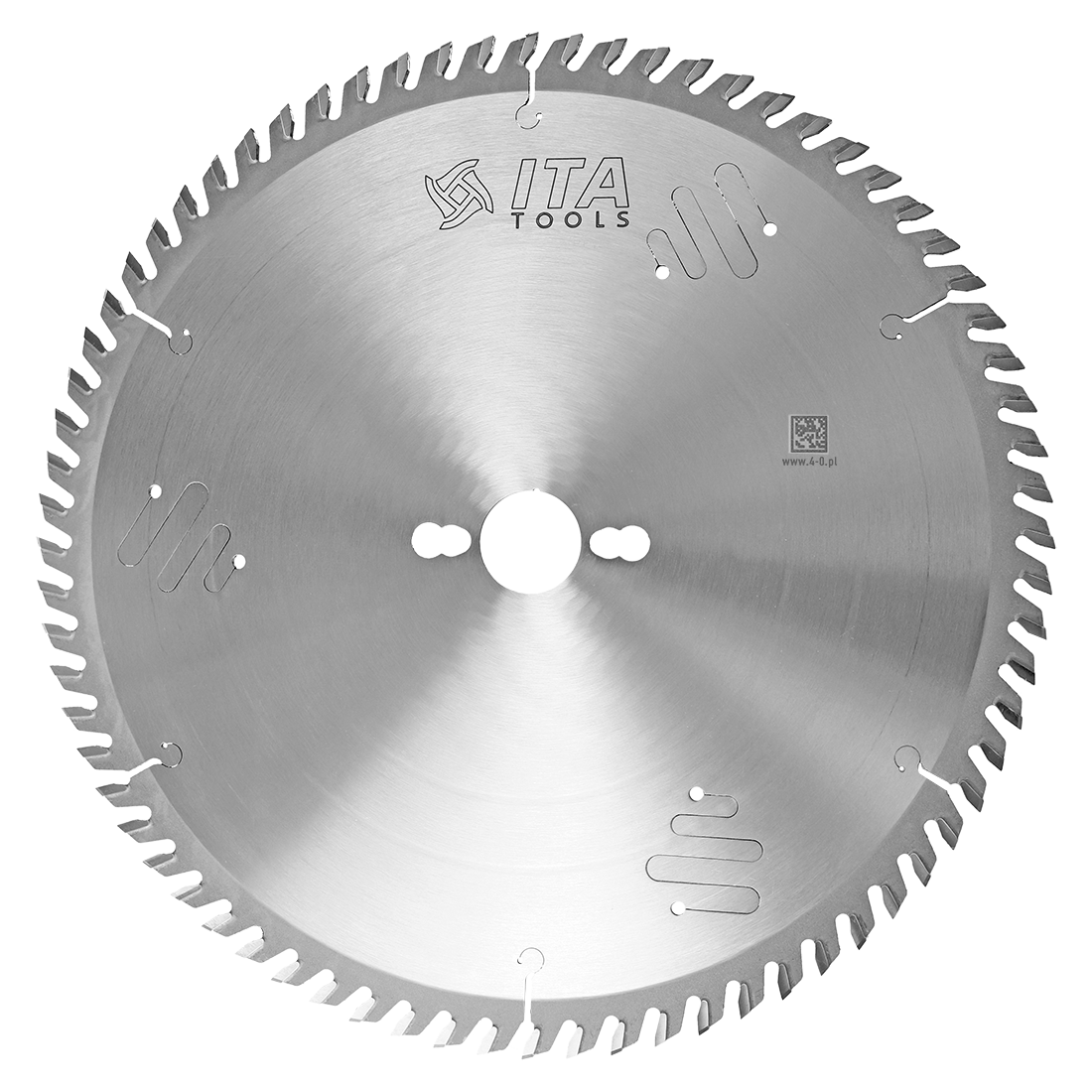

This applies to both classic format saw blades and panel saw blades. The range includes discs for machines such as HOLZMA, SCHELLING, HOLZ-HER, GIBEN, SCM, among others. The range for panel saws and format saws also includes the entire range of diamond scoring saws, which are increasingly replacing those with HM teeth.

P30 circular saw blades with NANO carbide

Since they appeared on the Polish market, panel saw blades of the P30 series with super-hard NANO carbide have been successively gaining an increasing number of satisfied customers who cannot imagine going back to previously used blades. There is a lot of cheap saw blades available on the Polish market, which, although attractively priced, are very inefficient. This is due to the use of cheap raw materials and the reduction of production costs at the expense of giving up additional quality control. This translates into a short service life of the saw and frequent disc defects, which are visible during operation.

The P30 series of panel saws with nanocarbide are designed for materials such as MDF, HDF. They are designed for cutting both individual panels and packages. The specially selected super-hard NANO carbide and the corresponding tooth profile (trapezoidal-straight) contribute to the long life of the saws and very good quality of machining.

Machine downtime is an undeniable loss, so manufacturing or cutting service companies try to keep machine downtime to a minimum. The most common reason for saw downtime is to change the cutting or undercutting saw, and then to gang them together. Nano carbide packet cutting saws are the ideal solution for companies looking to increase the saw's duty cycle, thereby reducing wastage due to machine downtime. The frequency of saw sharpening is also reduced, saving time and money.

A nanocarbon saw runs two to four times longer than saws previously used. The ideal set-up, allowing long working cycles without changing tools, is the P30 series saw as the main saw and the diamond pruner. The saw is ideal when machining laminated chipboard. It also works well for cutting HPL, which is an increasingly popular material in the furniture industry.

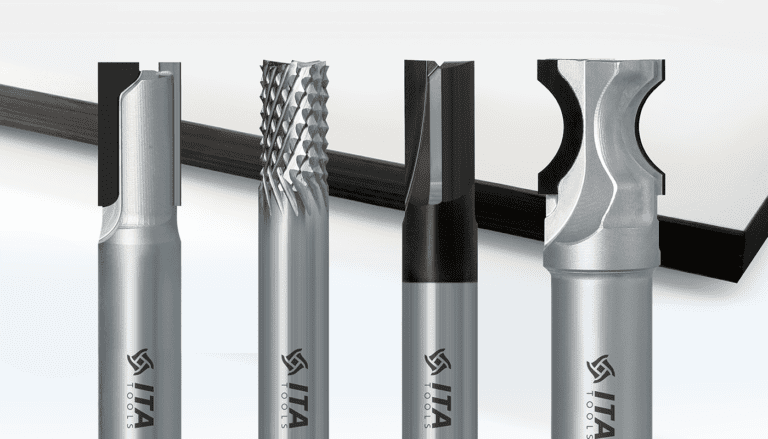

The perfect duo of tools

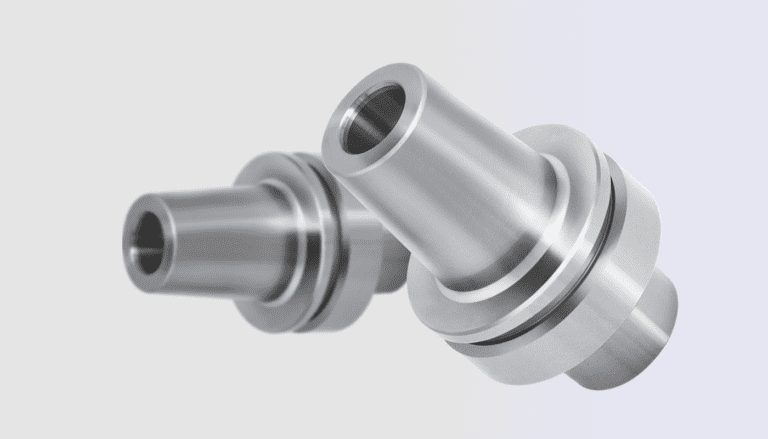

Many years of experience have shown that the most cost-effective and efficient is to use a set of HM saws and diamond scoring saws.

This combination brings many benefits to the customer. Among the advantages are up to 50 times longer service life compared to standard HM undercutters, as well as saving time and money by negating frequent changes and set-ups. The combination of discs with a diamond undercutter seems to be the best solution. Especially in the cutting of laminated chipboard and MDF on panel and format saws.

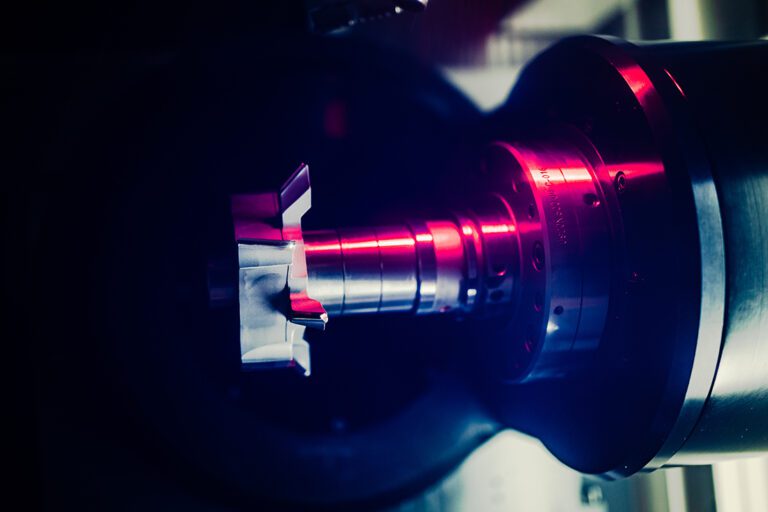

Diamond scoring saw - Service and reconditioning

In order to provide a comprehensive service for its partners, ITA TOOLS provides the following service sharpening and reconditioning diamond scoring saws. The sharpening shop located in Mielec has a modern fleet of machines where diamond tools are sharpened with the highest precision.

ITA TOOLS' comprehensive range of products and the multitude of options to choose from provide ample opportunity to select the most efficient cutting solution. A variety of circular saw blades for particleboard cutting on panel saws and format saws are available from stock. Importantly, customers can easily select the right saw blade for their machine using the professional catalogue available on the company's website. The necessary information can be found in B2B systemwhere, in addition to tools, the customer has access to, among other things, the current offer.