One of the basic machines that are used in woodworking firms are planers, in which feed rollers play an important role.

It is increasingly appreciated that feed rollers perform an important task on planning machines. The use of worn-out wheels means that the machine cannot work to its full potential. In addition, this prevents smooth operation, which reduces the use of wood material.

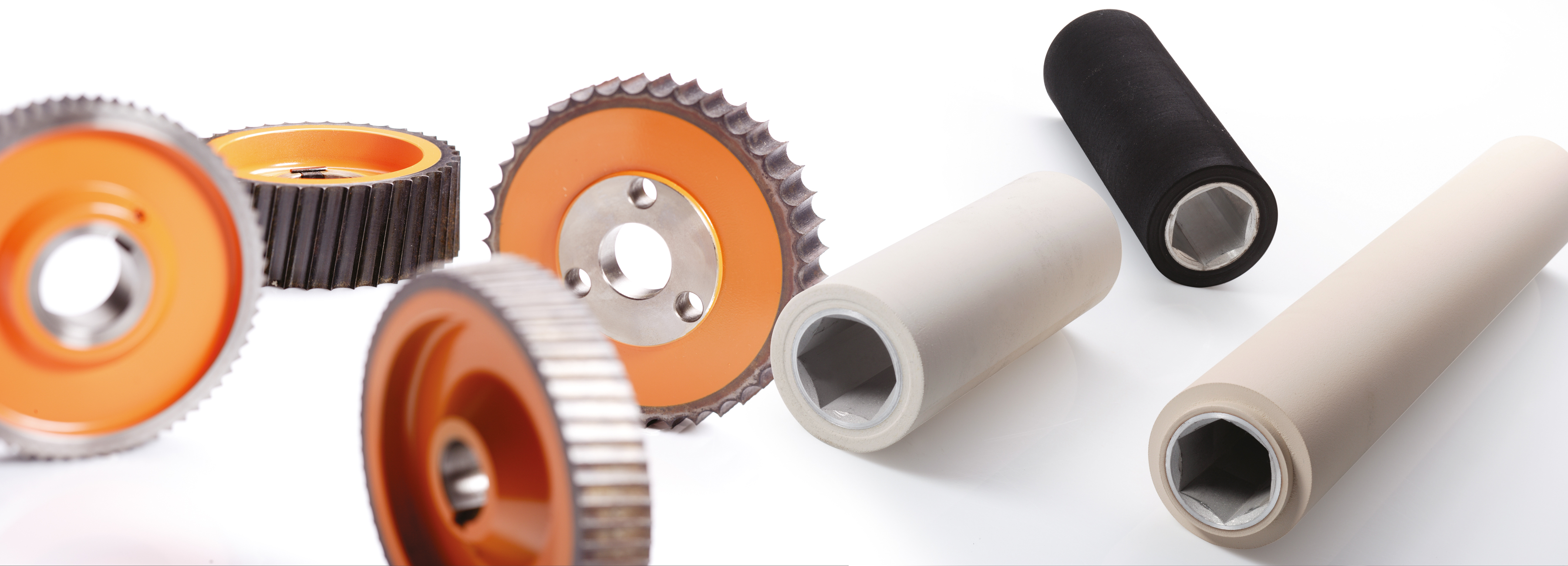

Feed rollers from ELASTOMERI

Due to the widespread use of planing machines, ITA TOOLS has established an exclusive distribution partnership in Poland with the Slovenian company ELASTOMERI. ELASTOMERI has been supplying feeding wheels for planing machines, edgebanders, thicknessers, trimming machines, glue spreaders and feeders for many years. Their products are available to customers not only in Europe, but all over the world.

The highest standards, quality assurance and production flexibility have earned this firm a position as one of the world leaders.

At the same time, we provide professional product advice from the Elastomeri brand, which develops its solutions based on many years' experiences, dating back to the 1970s. What sets this manufacturer apart from its competitors is certainly its wide range of products. The company guarantees that every customer can receive a roll designed specifically for their production process.

What makes them stand out?

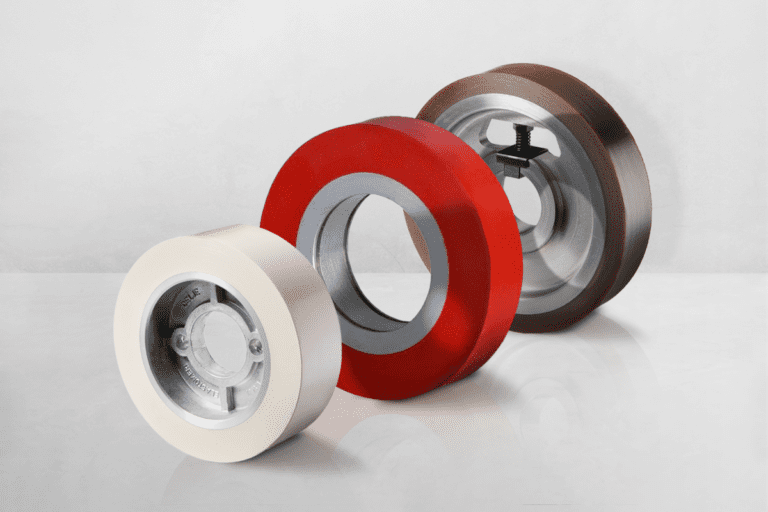

One of the strongest points in the Slovenian firm's product range are the steel feed rollers. They match both the type of material being processed and the machine on which the customer is working. The teeth on the steel rollers are designed based on existing solutions and the experience of four-sided planer operators from around the world.

The second major product group is plastic rollers, such as rubber, polyurethane, or silicone. The wide range of hardnesses makes it possible to select the type of roll exactly according to the customer's needs. An additional advantage is the ability to produce even customised special orders at short notice, which is particularly appreciated by owners of non-standard machines. In addition to new products, it is possible to recondition rubber rollers and shafts for wide-belt grinding machines.

We offer feed rollers for four-sided planers of all popular brands: WEINIG, SCM, GUBISCH, GUILLIET, LEDERMAC, WADKIN, HERBS, CHUET, FEDERER oraz HOMAG.